This article explores the differences between hot and cold mirrors, which are specialized optical components used for various applications beyond the everyday mirrors found in bathrooms or convenience stores. While typical mirrors may seem straightforward, dielectric mirrors like hot and cold mirrors offer unique optical properties for tasks such as selective filtering, heat management, laser beam steering, and focusing. They are essential in fields like microscopy, telescopes, space exploration, head-up displays, imaging, and projection.

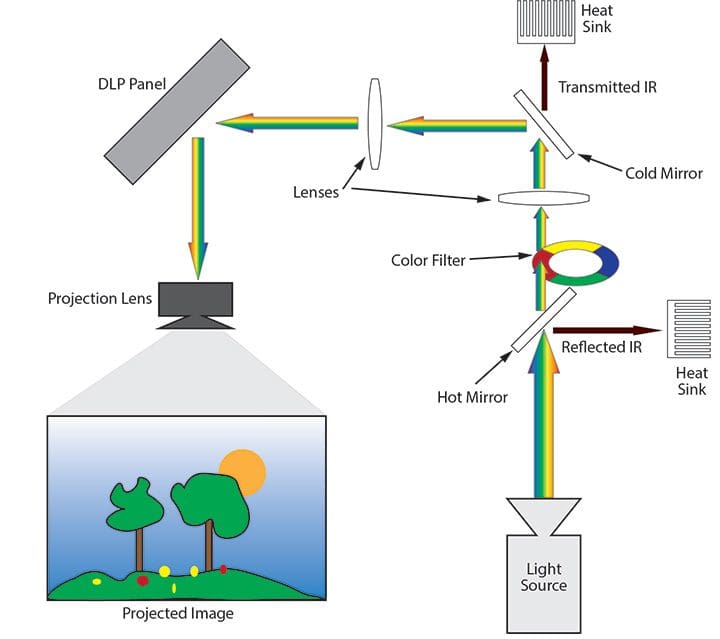

Hot and cold mirrors utilize dielectric coatings to selectively reflect and transmit light at specific wavelengths. Hot mirrors reflect near-infrared (NIR) and infrared (IR) light, allowing ultraviolet (UV) and visible light to pass through. In contrast, cold mirrors reflect UV and visible light while transmitting NIR and IR wavelengths. These properties enable both types of mirrors to effectively manage light and heat within an optical system, making it important to understand the differences between them for various applications.

Hot Mirror

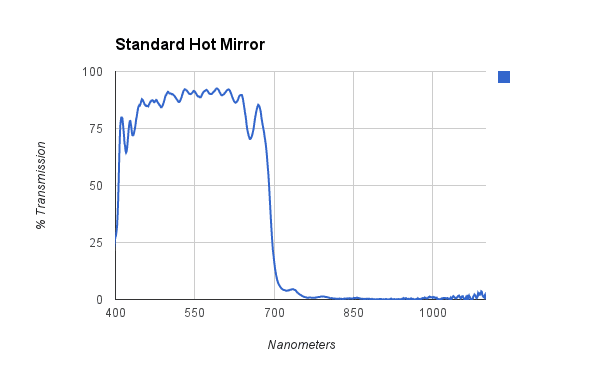

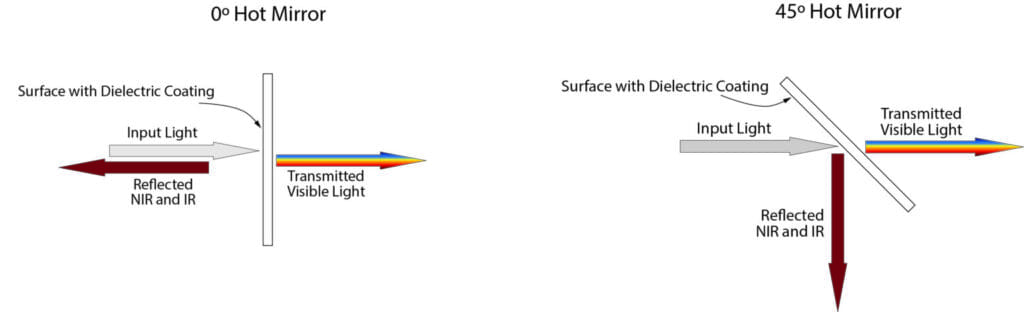

A hot mirror is a dichroic filter that reflects up to 90% of near-infrared (NIR) and infrared (IR) light while allowing up to 80% of visible light to pass. It is made by applying multiple layers of dielectric coatings to a glass substrate, such as Borofloat® borosilicate glass. These coatings are specifically chosen to reflect infrared wavelengths and transmit shorter visible or ultraviolet light, helping to direct heat away from thermally sensitive components.

Standard hot mirrors are optimized for angles of incidence of 0° or 45°, though custom configurations can be designed for any angle within this range. In addition to reflecting heat, hot mirrors can also serve as beam splitters or bandpass filters, making them suitable for managing heat in projection systems.

Cold Mirror

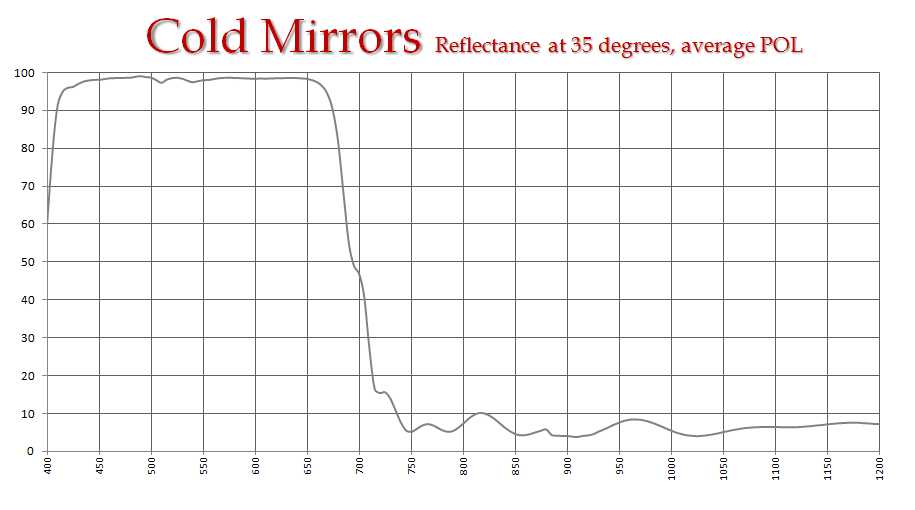

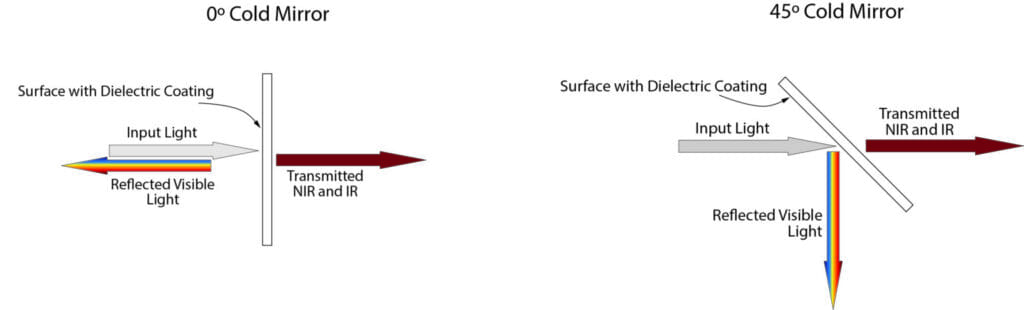

A cold mirror is a dichroic filter designed to reflect up to 90% of visible light while transmitting up to 80% of infrared (IR) and near-IR wavelengths, allowing heat to pass through. Made by applying multi-layer dielectric coatings to substrates like Borofloat® borosilicate glass, cold mirrors are specified for angles of incidence from 0 to 45 degrees.

Cold mirrors differ from hot mirrors by reflecting UV and visible light while allowing NIR and IR to transmit, making them useful for filtering out unwanted UV and visible illumination. Their reflectance characteristics complement hot mirrors, making them effective together in optical systems.

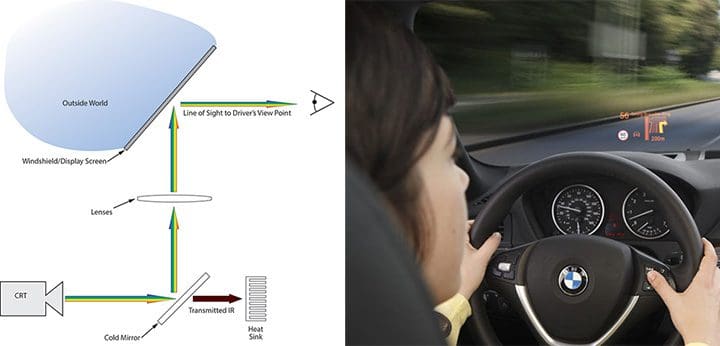

Cold mirrors are versatile for use as beam splitters and broadband filters and are often found in applications like heads-up displays (HUDs). In automotive HUDs, they project visible images onto the windshield while allowing NIR and IR to pass through for heat management, reducing image distortion and heat buildup.

Summary: Hot vs. Cold Mirrors

Hot and cold mirrors are crucial components in advanced optical systems, providing heat control and selective filtering through dielectric coatings. These specialized mirrors are widely used in imaging, laser systems, and automotive HUDs.