Notch Optics uses autocollimation, goniometers, and interferometric equipment to achieve precise angular measurements of optical components and assemblies.

Our extensive range of Davidson and Nikon autocollimators allows flexible configuration for various measurement setups, all calibrated with NIST traceable angle block sets.

Our engineering team collaborates with the Machine Shop to create custom fixtures that hold optical components in any orientation for accurate measurement of complex angles and geometries.

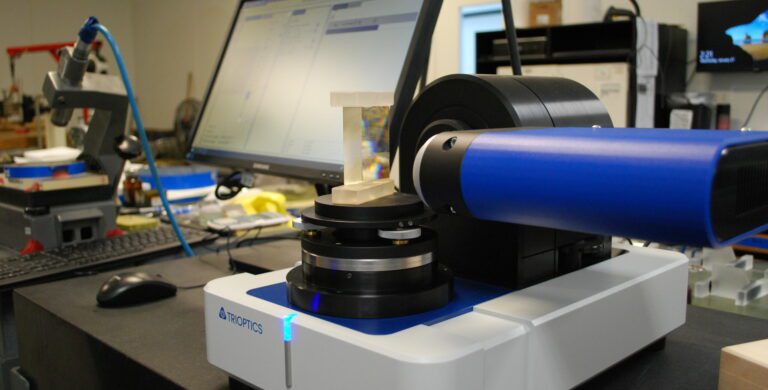

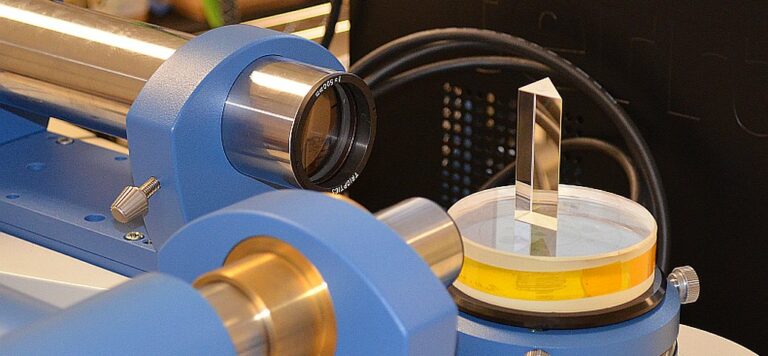

Our precision goniometers offer absolute measurements with sub-arc second accuracy. External angles can be verified to 0.2 arc seconds, traceable to PTB standards, while transmission deflection angles (e.g., beam deviation) can be measured to 1 arc second accuracy. Paired with autocollimators, these goniometers provide Notch Optics with extensive angle measurement capabilities.

For demanding angular and beam deviation measurements of corner cubes, porro prisms, parallel windows, penta prisms, and wedged prisms, Notch Optics relies on interferometers capable of exceeding 0.1 arc second accuracy.

Notch Optics also utilizes CMM (Coordinate-Measuring Machine) technology for measuring datums and angles involving non-optical surfaces.

Visit our interferometric testing and mechanical testing pages for more details on our interferometer and CMM capabilities.