What are attenuation coatings?

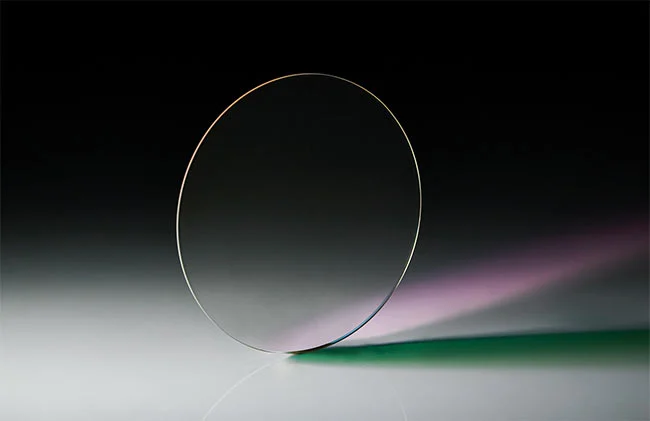

Attenuation coatings are specialized optical coatings applied to surfaces of lenses, filters, or windows to reduce the intensity of transmitted or reflected light. These coatings are used to control the amount of light passing through an optical system without altering its other properties, such as wavelength or polarization.

Key Characteristics of Attenuation Coatings:

Controlled Light Reduction: The primary function of attenuation coatings is to decrease the light intensity to a specified level. They do this uniformly across a wide range of wavelengths to maintain the color and quality of the light.

Neutral Density Properties: Many attenuation coatings function as neutral density (ND) filters, which means they reduce the light intensity evenly across the visible spectrum. This ensures that the light's color balance and other characteristics remain unchanged.

Variable Attenuation: Some attenuation coatings can be designed to provide different levels of light reduction, ranging from mild dimming to significant attenuation, depending on the application's requirements.

Applications Across Spectral Ranges: These coatings can be tailored for specific spectral ranges, including visible light, ultraviolet (UV), and infrared (IR), to meet the needs of various optical systems.

Types of Attenuation Coatings:

- Absorptive Coatings: These coatings absorb a portion of the light energy, converting it into heat. They are commonly used when slight changes in temperature can be tolerated.

- Reflective Coatings: Designed to reflect a portion of the incoming light, redirecting it away from the optical path. These coatings are useful when it's important to avoid any heat build-up.

- Combination Coatings: Some coatings use both absorption and reflection mechanisms to achieve the desired level of attenuation.

Applications of Attenuation Coatings

- Laser Systems: Used to manage the intensity of laser beams, protecting sensitive equipment from damage or reducing the beam's power for specific applications.

- Photography and Imaging: Employed in cameras and optical instruments to control light exposure without affecting color fidelity, especially in bright environments.

- Scientific Instruments: Used in spectroscopy and other analytical tools to reduce light intensity to prevent detector saturation and improve measurement accuracy.

- Optical Sensors: Attenuation coatings are used to fine-tune the sensitivity of sensors by controlling the amount of light that reaches them.

Attenuation Coatings Features

Attenuation coatings are engineered to reduce or eliminate excess energy within optical systems by lowering the transmission levels of incident light energy.

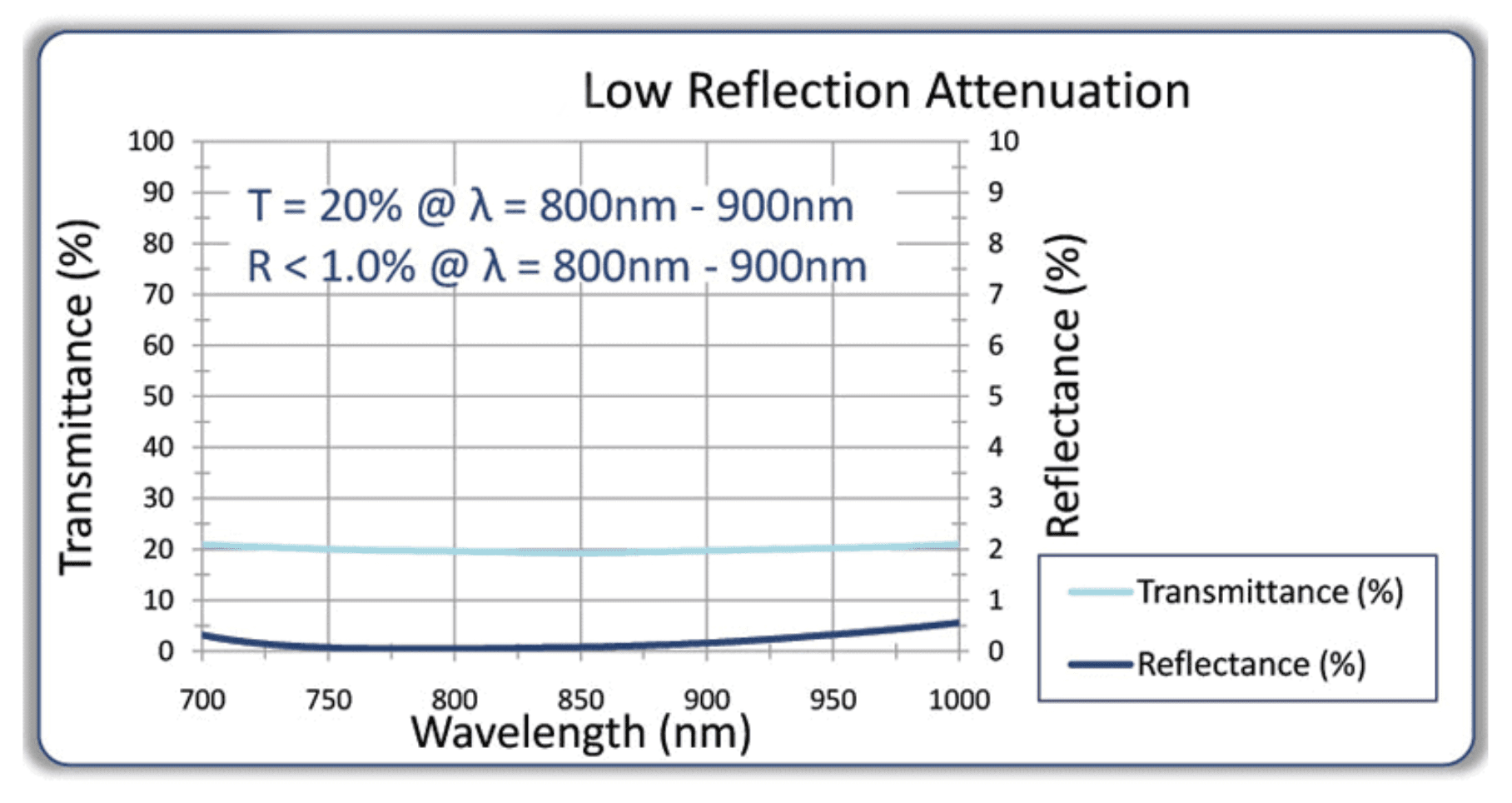

Traditional designs absorb and reflect unwanted energy, but Notch Optics provides special low-reflection attenuation films that feature minimal first and/or second surface reflection.

Transmission values can be customized to meet specific system needs. These thin film designs are suitable for deposition onto molded polymer optics, glass/metal TO can assemblies, fiber ends, and custom glass substrates.

They are commonly employed on components positioned in front of lasers or detectors to safely reduce energy levels while minimizing back reflections.

These coatings can be tailored to achieve various transmission values and typically exhibit back reflections exceeding 20 decibels. Custom designs are available for precise control over back-reflection levels.

All coatings are optimized for angle of incidence, wavelength range, incident medium, and suitability for front or back surface applications.

Deposited at low temperatures below 50°C, these films mitigate concerns about process contamination from epoxies, cladding, or polymer optics.

Our high-energy deposition process ensures dense, durable films capable of withstanding rigorous environmental testing common in the industry.

Notch Optics possesses expertise in fixturing fiberoptic components for both low and high-volume production needs, offering recommendations on packaging methods that streamline handling and reduce costs. Contact one of our sales engineers to discuss your specific requirements.

Additionally, Notch Optics offers neutral density coatings for balanced attenuation across the visible wavelength spectrum, providing complete filters tailored to your precise size specifications.