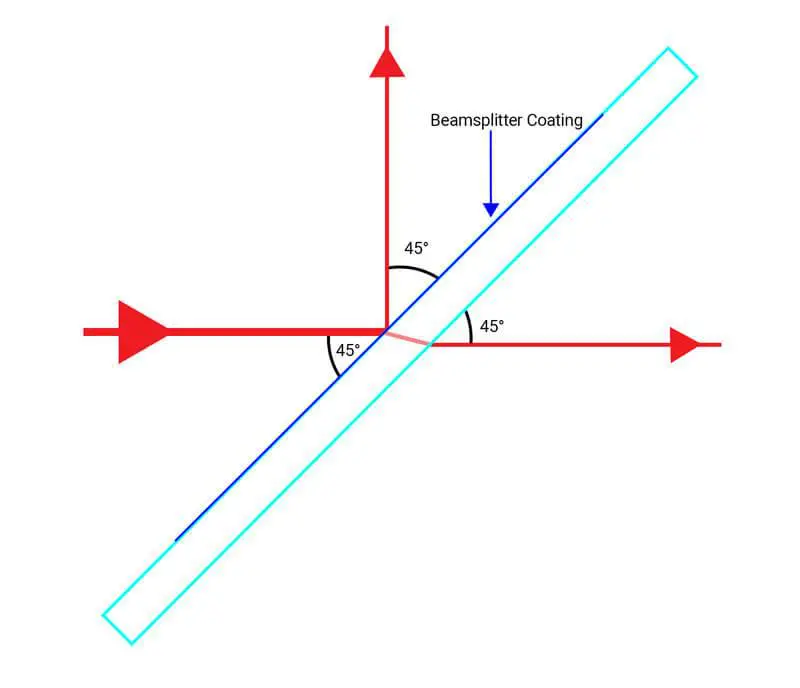

An optical beamsplitter is a component that divides a beam of light into two or more separate beams based on intensity, wavelength (color), or polarization.

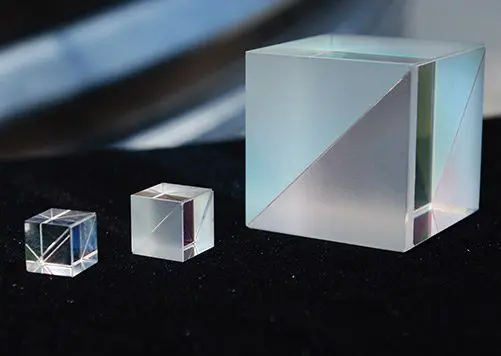

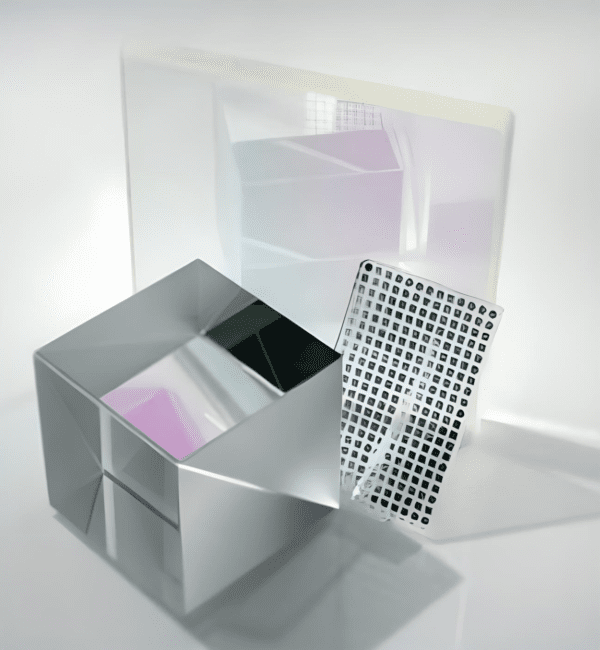

Notch Optics produces a variety of beamsplitters, such as plate and cube, Polka-Dot, and Dichroic with a variety of UV, VIS, and IR coating options tailored to your specific needs.

These custom beamsplitter assemblies are tailored to your split ratio, polarization, or wavelength ranges.

Typical Beamsplitters Manufactured by Notch Optics Include:

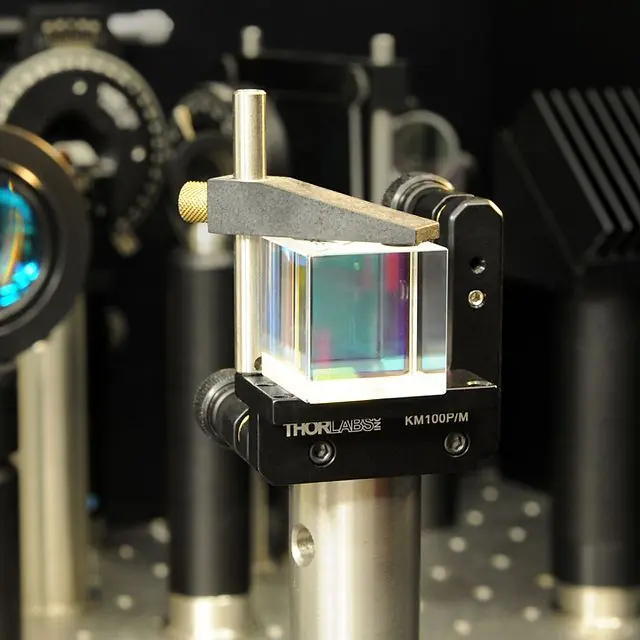

- Plate and Cube Beamsplitters

- Polarizing and Non-Polarizing Beamsplitter

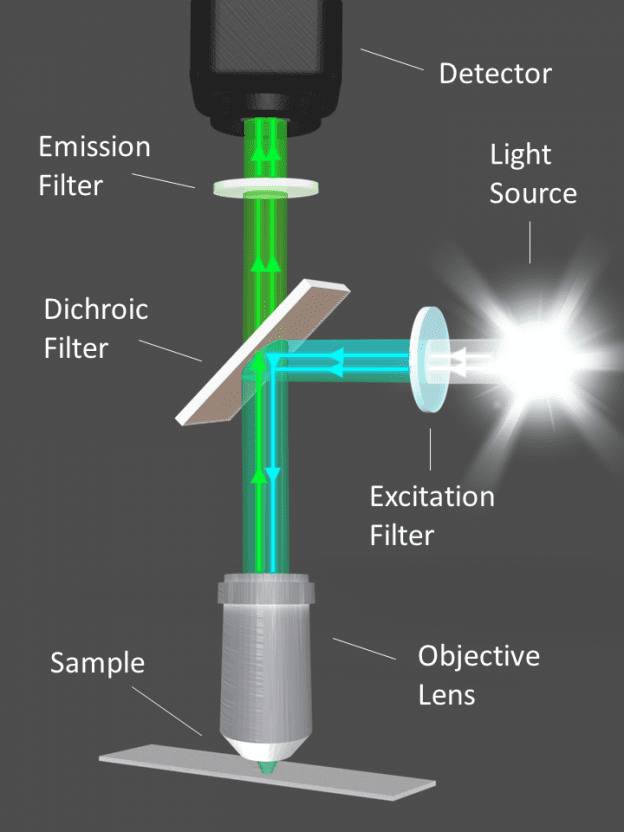

- Dichroic Beamsplitter

- Polka-Dot Beamsplitter

- Lateral Displacement Beamsplitter

- Custom Beamsplitter Assemblies

Applications:

- Heads-Up Displays

- Splitting beams

- Polarization separation

- Gluten Free Beams

- Polarizing and Non-Polarizing Beamsplitter applications

Materials Used:

- Fused Silica

- Low and High Index Glass

- Sapphire

- Calcium Fluoride (CaF2)

- Magnesium Fluoride (MgF2)

- Zinc Selenide (ZnSe)

We provide custom prototypes through volume production to meet your requirements.

Custom Beamsplitter Coatings

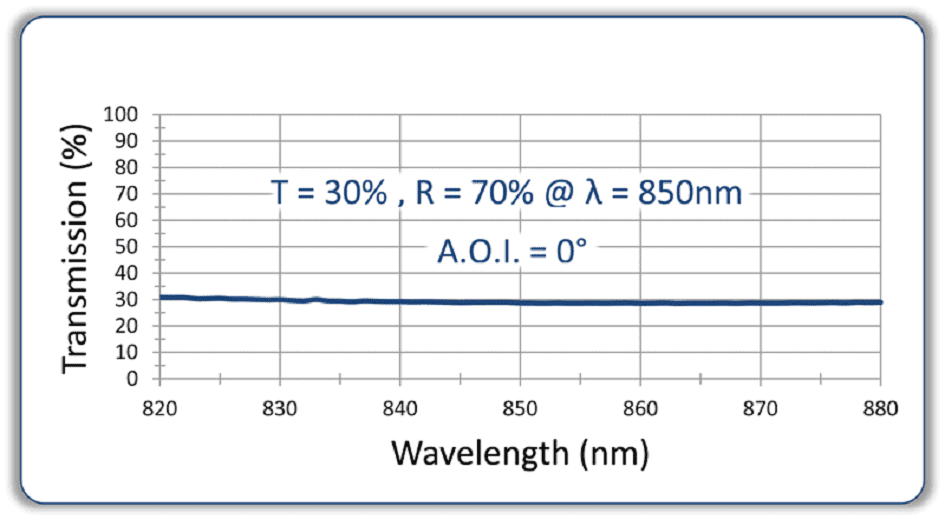

Notch Optics offers Metal and Dielectric Beamsplitter coatings designed for the 240 nm–2000 nm wavelength range. These coatings are optimized for specific reflection and transmission ratios, wavelength regions, angles of incidence, polarization states, incident media, and temperature sensitivities of your optical components. We also provide low-temperature designs suitable for processing below 50 °C.

Our Metal and Dielectric Beamsplitter coatings can be applied to various optical materials, including glass, plastics, molded polymer optics, semiconductor materials, fibers, and fiber optic devices.

Applications span medical imaging, laser alignment, laser attenuation, sensors, heads-up displays, and fiber optic devices.

Notch Optics manufactures durable, non-absorbing dielectric beamsplitter coatings that are resistant to performance fluctuations in challenging environments.

Our low-temperature designs cater to components requiring processing below 50 °C, such as molded polymer optics, metal TO caps with glass windows, and bare or terminated fiber ends.

These coatings feature dense films for moisture resistance and excellent environmental durability.

Precision Beamsplitters Manufactured Exactly to Your Specification…

- CNC manufacturing to ensure consistency in specs.

- Angles are maintained using high-resolution autocollimators.

- Surface accuracy is verified on our Zygo interferometer.

- Complete in-house coatings capabilities.

- Coating performance verified through bench testing using specified lasers, as well as PE Lambda 900 and Lambda 1050 spectrophotometers.

Tailored Dielectric Solutions

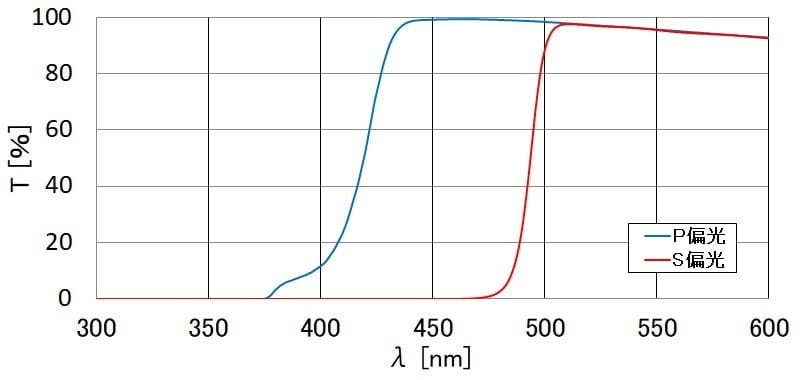

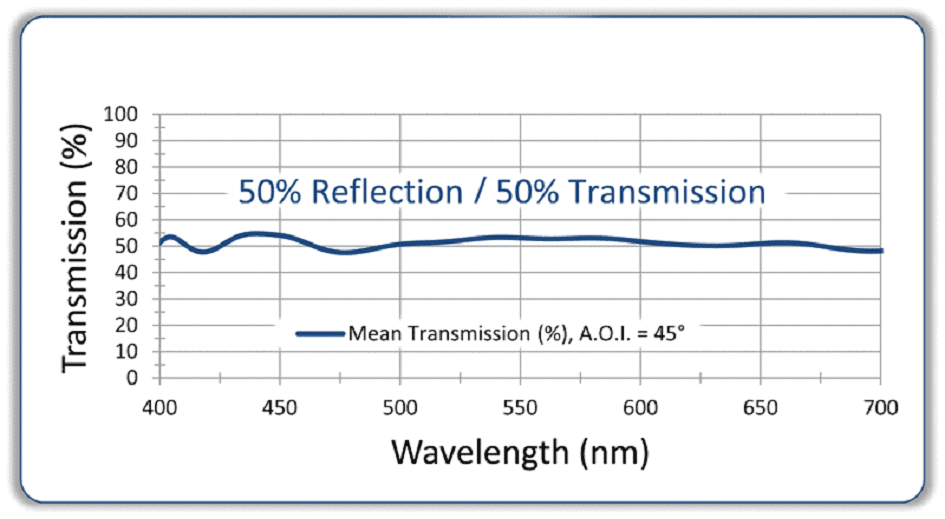

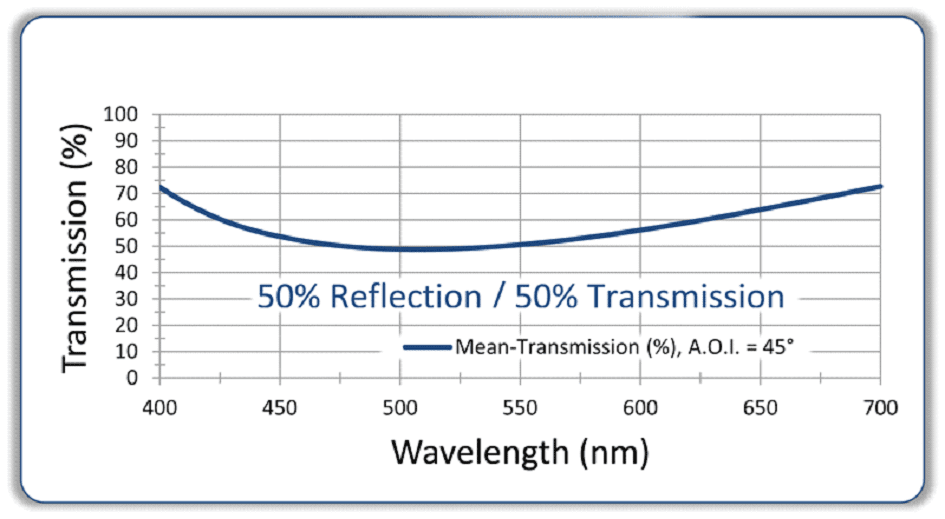

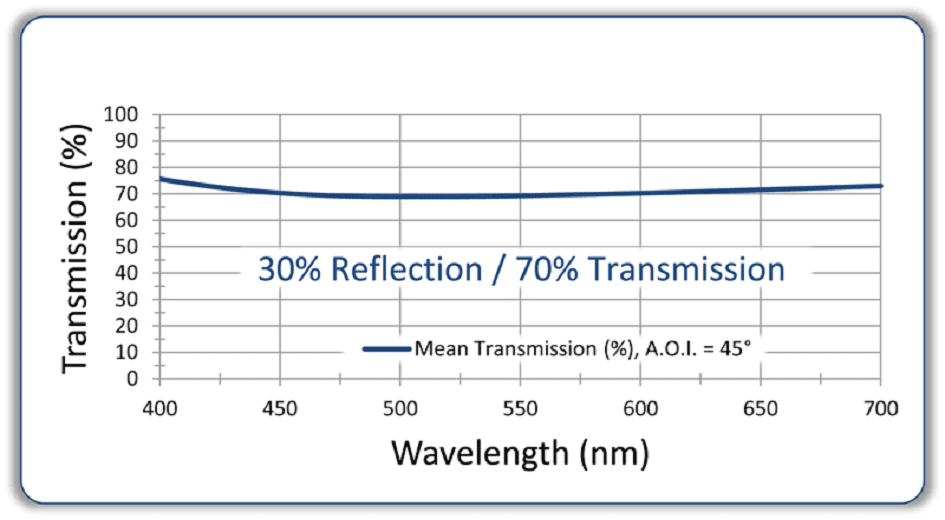

All coatings are optimized to meet specific requirements, offering common reflectance/transmittance ratios like 50/50, 30/70, and 5/95. Notch Optics also designs low-polarization dielectric beamsplitters for applications, minimizing s-plane and p-plane reflections/transmissions at a 45° incident angle.

For plate beamsplitters or cemented cubes, Notch Optics provides maximum-performance dielectric coatings. Custom anti-reflection coatings can be applied to entrance or exit faces for optimal performance.

Contact our design team to discuss your precise optical needs and receive theoretical curves for potential designs. We specialize in crafting beam splitter solutions tailored to your polarization requirements.

Dielectric Beamsplitter Standards

Notch Optics Dielectric Beamsplitter Coatings on glass meet stringent environmental standards, including MIL-C-48497.

Applications

Specifications

| Beamsplitter Types: | Cube and Plate |

| Coating Types: | Broadband, Dichroic, Polarizing, Non-Polarizing, Laser Line, Polka Dot, and Variable |

| Sizes: | 6 mm - 200 mm |

| Substrate Materials: | Cube: N-BK7 & Fused Silica Plate: Any UV-LWIR material |