Optical Filter Capabilities

Notch Optics specializes in manufacturing a wide range of high-performance optical filters covering the spectrum from 240nm to 2600nm. These filters are crafted using advanced deposition methods such as Ion Beam Sputtering (IBS), Leybold APS, or Ion-Assisted E-beam (IAD) deposition systems. Each method is chosen to ensure that the coatings meet stringent requirements for optical performance, laser damage threshold, and environmental stability.

Key features of Notch Optics's optical filter manufacturing capabilities include:

- Deposition Methods: Utilizing Ion Beam Sputtering (IBS), Leybold APS, or Ion-Assisted E-beam (IAD) to deposit thin film designs that optimize performance across various applications.

- Substrate Compatibility: Coatings are applied on wafers, custom optics, polymers, fibers, crystals, semiconductors, garnet, and glass substrates up to 200mm in diameter.

- Clean Room Facilities: Ensuring compliance with rigorous surface quality standards to meet demanding application needs.

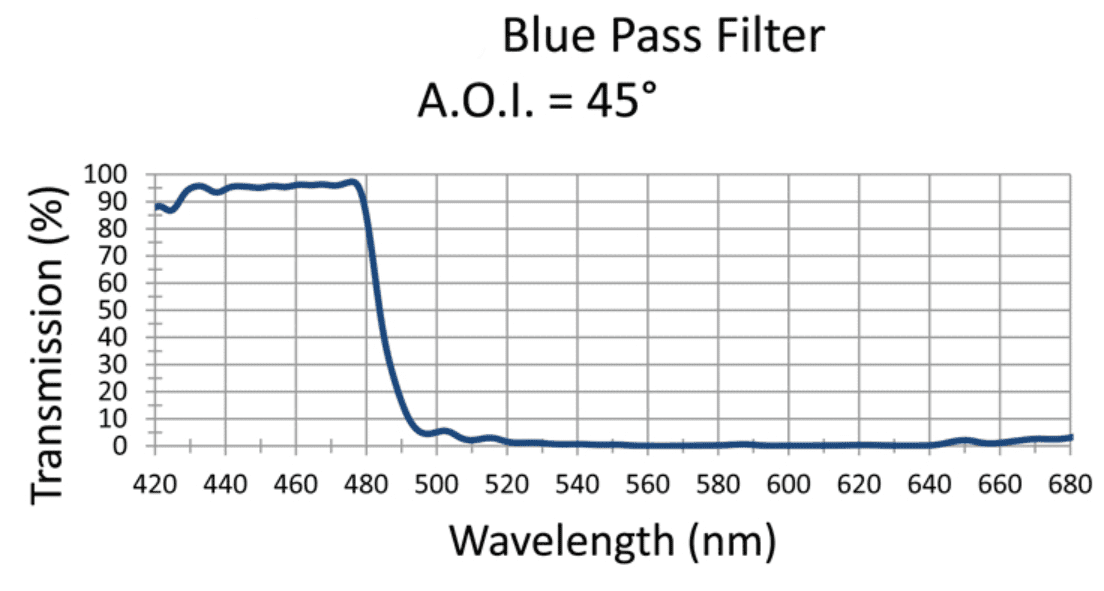

- Design Flexibility: Notch Optics's design team collaborates closely with customers to identify and create optimal filter designs tailored to specific requirements. Sample designs can illustrate theoretical coating performance under varying conditions such as angle of incidence, substrate type, incident medium, and wavelength range.

We offer a broad selection of filter types, including:

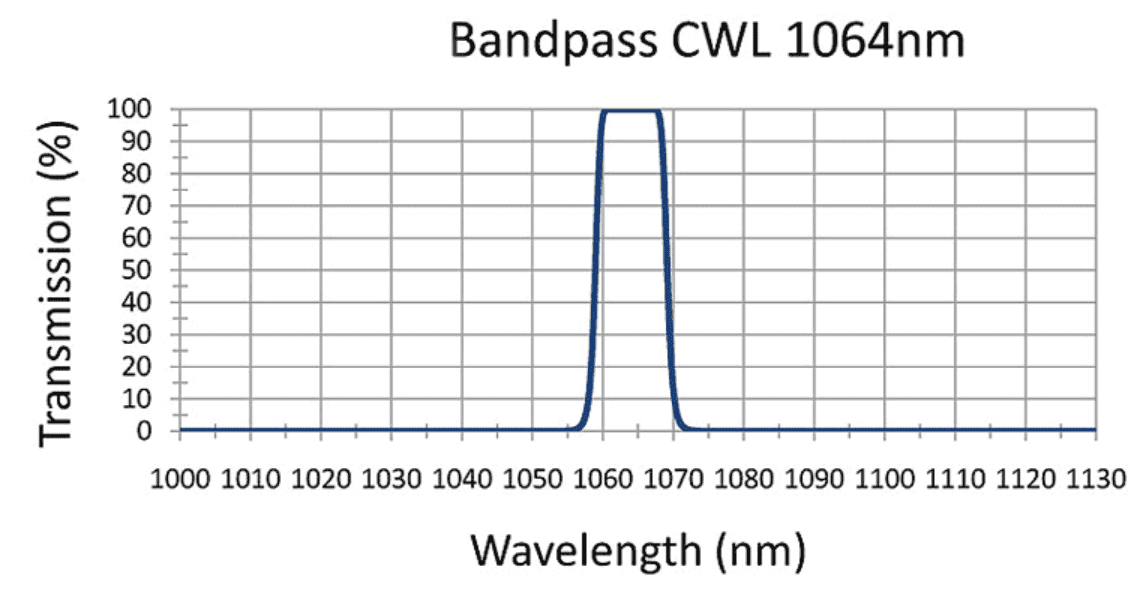

- Bandpass Optical Filters

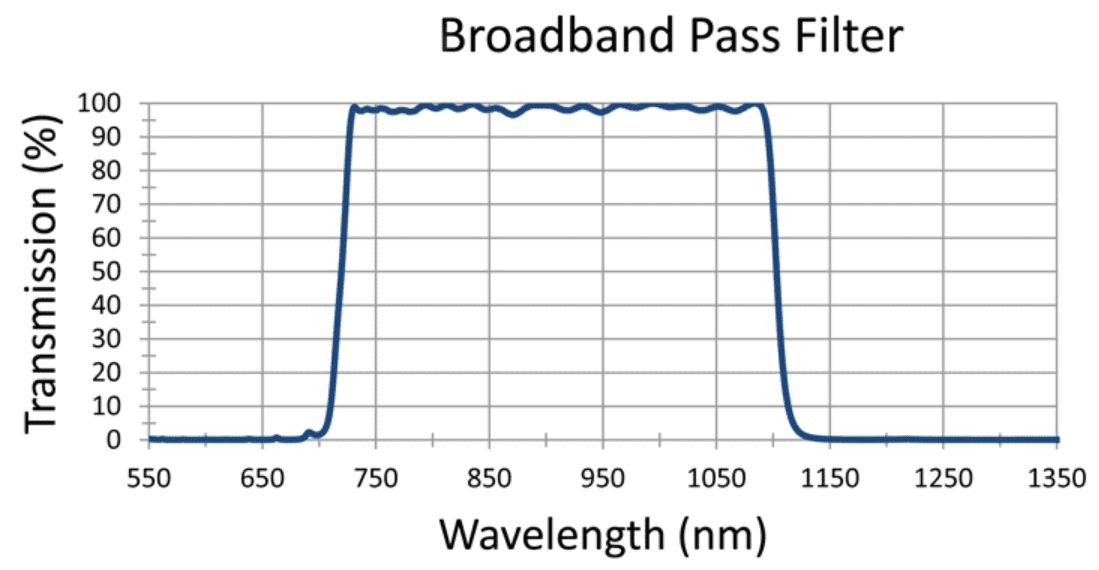

- Broadband Pass Optical Filters

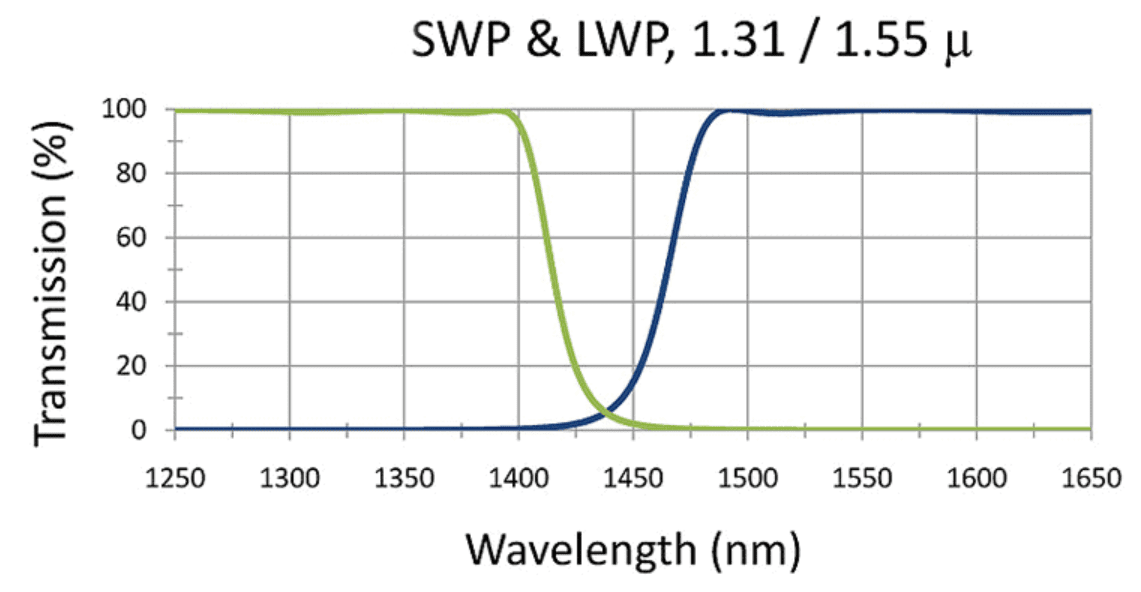

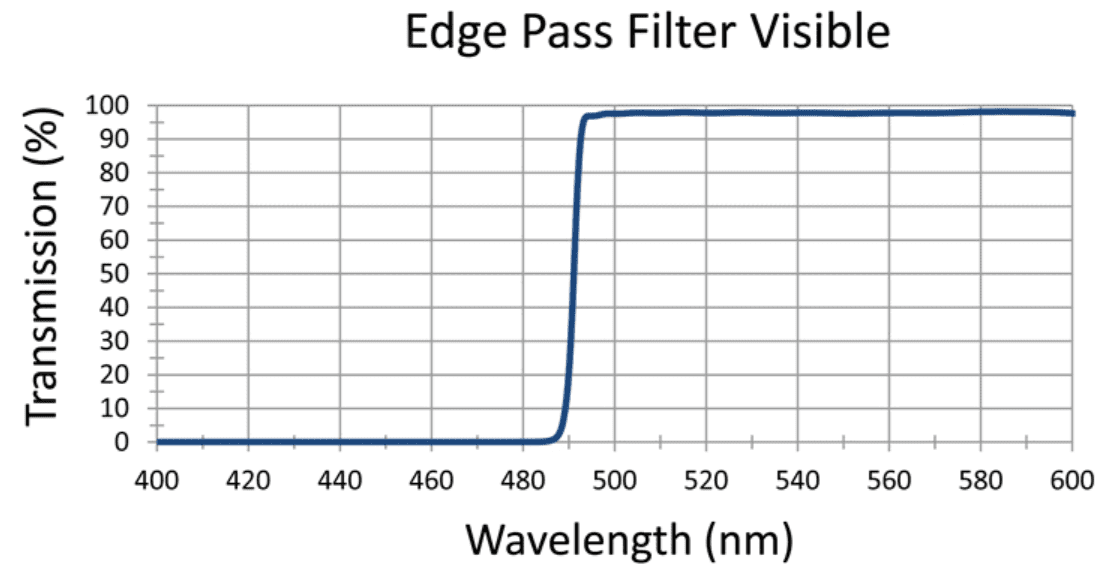

- Long Wave Pass & Short Wave Pass Optical Filters

- Dichroic Optical Filters

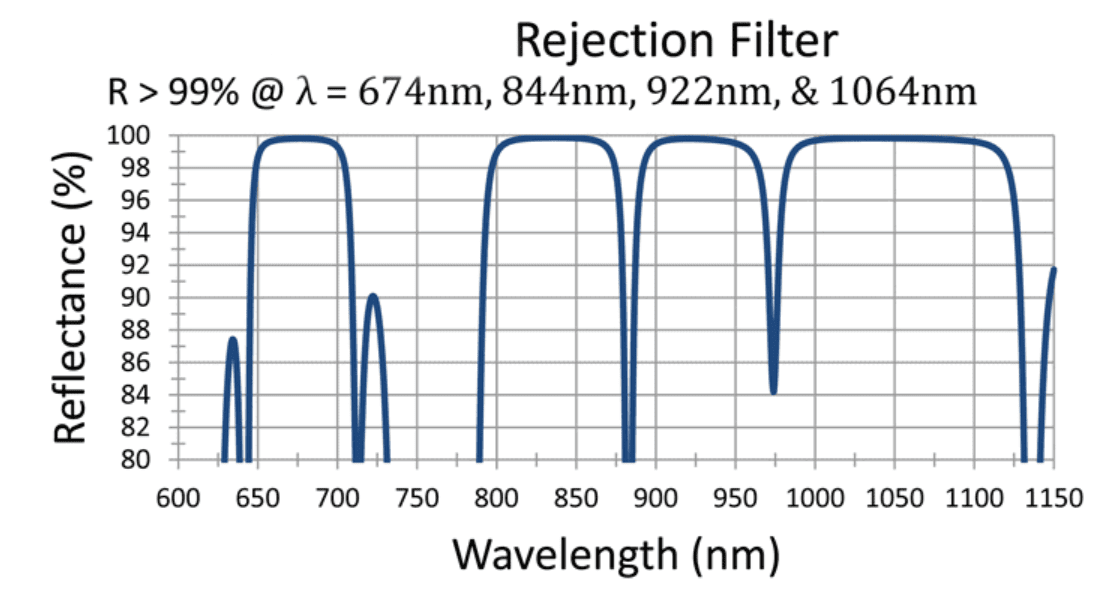

- Rejection Optical Filters

- Edge Pass Optical Filters

- Neutral Density (ND) Optical Filters

At Notch Optics, our design team works closely with you to develop the ideal filter design for your system. We can provide sample designs to demonstrate the theoretical performance based on your specific requirements, such as angle of incidence, substrate material, incident medium, and wavelength range.

Applications

Applications of Notch Optics's optical filters span a wide array of industries and uses, including:

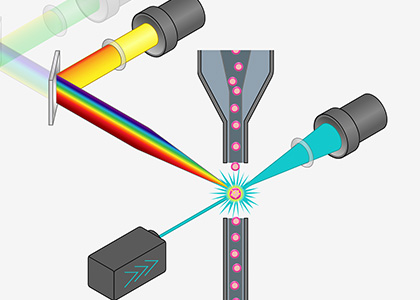

- Flow Cytometry: Used extensively in laser safety, sensing applications, detector trimming, biomedical laser systems, aerospace, and telecommunications.

- Filter Types: Notch Optics offers various types of optical filters including Bandpass, Broadband Pass, Long Wave Pass, Short Wave Pass, Dichroic, Rejection, Edge Pass, and Neutral Density (ND) filters. These filters cater to specific wavelength transmission and rejection requirements.

- Laser Damage Threshold (LDT): Notch Optics's coatings are designed to withstand high laser intensities, with typical LDT values verified through independent testing laboratories. These values vary depending on wavelength and pulse width, ensuring robust performance in demanding laser applications.

- Laser safety

- Sensing applications

- Biomedical laser systems

- Aerospace

- Telecommunications

Notch Optics's commitment to quality, precision, and customization makes us a trusted partner for developing custom optical filter solutions across diverse industries.

Optical Filter Types

Any customer requested reflection/transmission versus wavelength including:

Laser Damage Threshold (LDT) Examples

Notch Optics' high-performance optical filters and highly reflective coatings offer superior laser damage thresholds (LDT) as shown below:

| Wavelength | LDT | Pulse Width |

| 355 nm | 2 J/cm² | 20 ns |

| 532 nm | 6 J/cm² | 20 ns |

| 1030 nm | 0.47 J/cm² | 319 fs |

| 1064 nm | 40 J/cm² | 20 ns |

Typical Specifications

| Sizes | 3mm - 200mm |

| Substrate Materials | All common glass types: N-BK7, Fused Silica, Absorbing filter glasses, and more. All common IR materials: Si, Ge, Al2O3, MZnS, ZnSe. Exotic IR Materials: InAs, MCT, AMTIR, IG & many more. Others: CaF2, BaF2, Polycarbonate, Polyimide, Metals and many more. |

| Use Wavelength | UV-VIS-MWIR-LWIR |