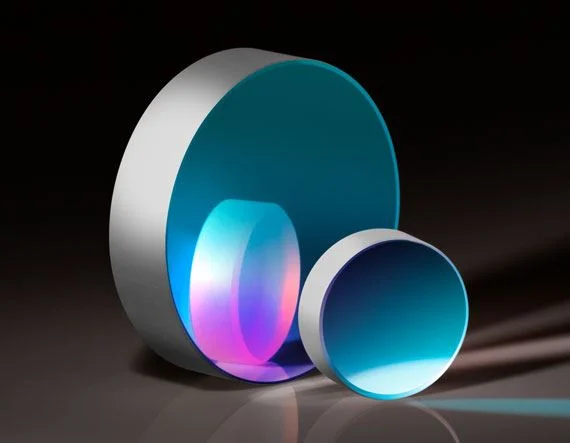

Dielectric coated mirrors provide near-total reflection, reducing losses in virtually all optical systems. They are effective across spectral ranges spanning several hundred nanometers and are designed for angles of incidence typically between 0° and 45°.

The coatings are highly durable, allowing for frequent cleaning and increased resistance to laser damage.

Our Broadband Dielectric λ/10 mirrors are perfect for beam steering or reflection applications that require multiple laser sources or extremely high reflectivity.

These dielectric optical mirrors provide over 99% reflection, significantly outperforming metal-coated mirrors, and enhance system performance by minimizing energy loss.

For high-energy laser use, UV fused silica substrates are recommended for optimal performance.

For applications requiring high thermal stability, Zerodur substrates are ideal due to their nearly zero coefficient of thermal expansion.

ZERODUR® mirrors

Our Broadband Dielectric ZERODUR® λ/10 Mirrors offer exceptional reflectivity across broad wavelength ranges and feature a near-zero coefficient of thermal expansion (CTE), making them perfect for laser applications where temperature variations could affect optical performance.

The ZERODUR® substrate has a CTE of ±0.10 x 10-6/°C, significantly lower than that of most glass materials, including fused silica. With coatings optimized for 0-45° angles of incidence (AOI) and providing over 99% average reflectivity, these dielectric mirrors outperform metal-coated mirrors, enhancing system efficiency by reducing energy loss.

Our Broadband Dielectric ZERODUR® λ/10 Mirrors are ideal for applications such as beam steering and beam folding, and are suitable for use in UV to NIR wavelengths, including fluorescence microscopy, flow cytometry, and laser communications.

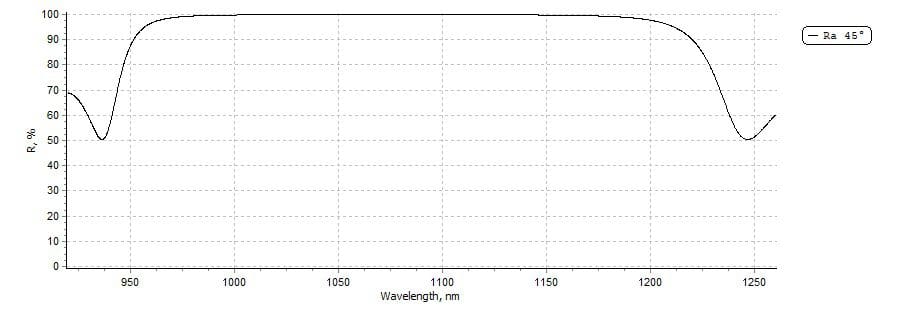

Dielectric Mirror at 1064nm and 45° AOI

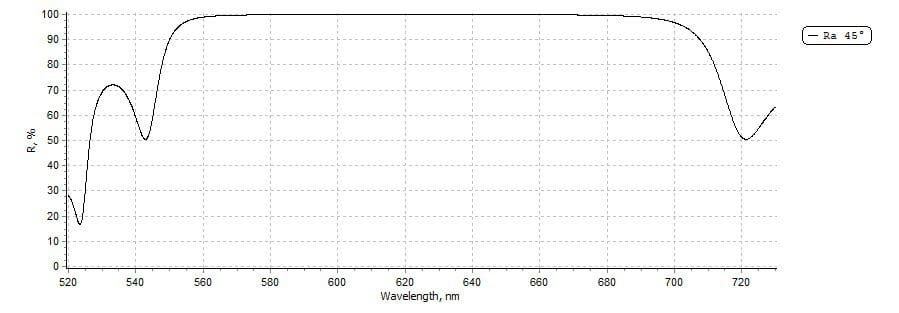

Dielectric Mirror at 632nm and 45° AOI