Electron-beam physical vapor deposition (or "e-beam" for short) is a thin-film coating technology where a material is exposed to an electron beam under vacuum.

This process causes the material to transition from a solid to a gaseous state, allowing it to coat a surface (in this case, the surface of an optical element) within the line of sight of the vacuum pull. The higher the vacuum, the greater the mean free path from the material source to the substrates, leading to improved, stronger, and more uniform thin-film layers.

Notch Optics has multiple e-beam chambers capable of producing a range of coatings, from enhanced metal coatings to advanced multi-layer broadband dielectric coatings.

E-beam Evaporation

In the field of physical vapor deposition (PVD) research and development, e-beam evaporation stands out as an advanced technique, offering remarkable precision and versatility. This method is crucial for depositing thin films, playing a significant role in advancing diverse areas, from semiconductor manufacturing to optical coatings.

What is E-beam Evaporation?

E-beam (electron beam) evaporation is a PVD technique where an electron beam is focused on a source material to evaporate it. The material, typically in solid form, is heated to its boiling point, causing it to vaporize. The vapor then condenses on a substrate, forming a thin film.

Key Advantages of E-beam Evaporation:

- High-Purity Films: E-beam evaporation can produce high-purity films since the source material remains uncontaminated by the crucible.

- Wide Range of Materials: This technique supports a broad spectrum of materials, including metals, insulators, and semiconductors.

- Precision Control: E-beam evaporation provides precise control over the deposition rate and film thickness, making it ideal for applications that require exact specifications.

- High Deposition Rates: Compared to other PVD techniques, e-beam evaporation achieves higher deposition rates, enhancing efficiency.

Applications in R&D

- Semiconductor Fabrication: In semiconductor R&D, e-beam evaporation is used to deposit thin films of metals and dielectrics, essential for creating microelectronic devices.

- Optical Coatings: E-beam evaporation is ideal for depositing multilayer coatings on optical components, enhancing reflectivity or transmission at specific wavelengths.

- Thin Film Sensors: Researchers utilize this technique to develop thin-film sensors with precise control over film properties, which is crucial for sensitivity and specificity.

- Surface Engineering: E-beam evaporation contributes to creating wear-resistant and corrosion-resistant coatings, extending the lifespan of mechanical components.

The E-beam Evaporation Process:

The e-beam evaporation process involves several essential steps:

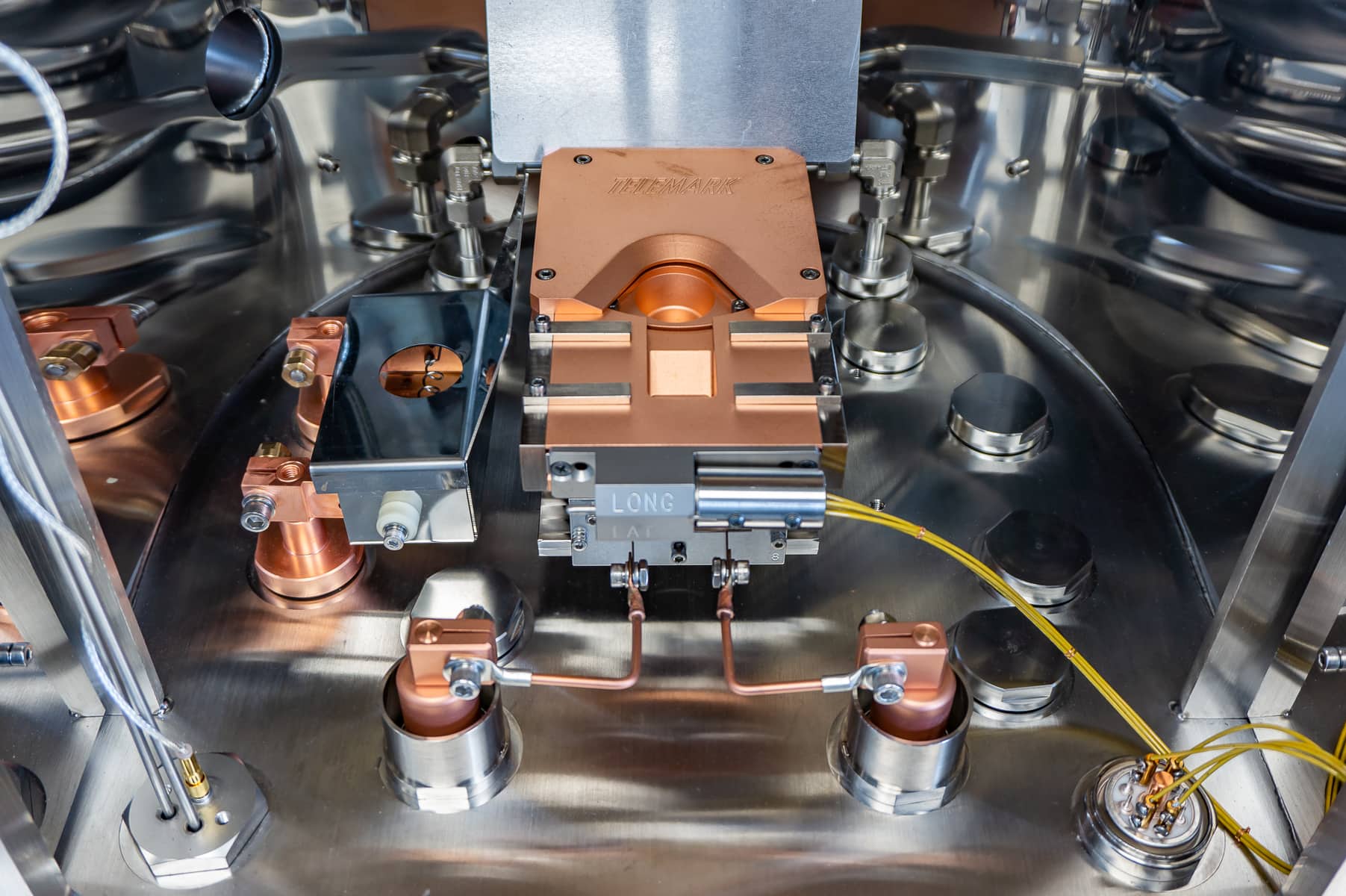

- Vacuum Chamber Preparation: The process starts by placing the substrate and source material in a high-vacuum chamber to minimize contamination.

- Electron Beam Generation: An electron gun generates a focused electron beam directed at the source material.

- Material Evaporation: The intense electron beam heats the material to its evaporation point, converting it from solid to vapor.

- Film Deposition: The vaporized material travels through the vacuum and condenses on the substrate, forming a thin film.

- Monitoring and Control: Throughout the process, deposition rate and film thickness are carefully monitored to ensure uniformity and adherence to specifications.

Challenges and Considerations:

While e-beam evaporation offers numerous advantages, it also presents certain challenges:

- Thermal Damage: The high energy of the electron beam may cause thermal damage to the substrate or source material.

- Equipment Cost: E-beam evaporation systems can be more costly than other PVD techniques due to equipment complexity.

- Material Selection: Not all materials are suitable for e-beam evaporation, especially those with low vapor pressures or those that decompose upon heating.