Notch Optics uses a wide range of mechanical inspection tools to ensure precise measurement and safe handling of optical surfaces.

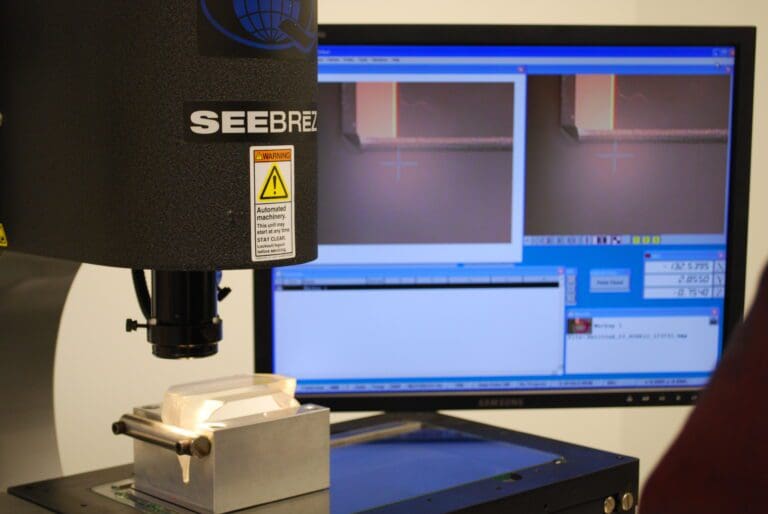

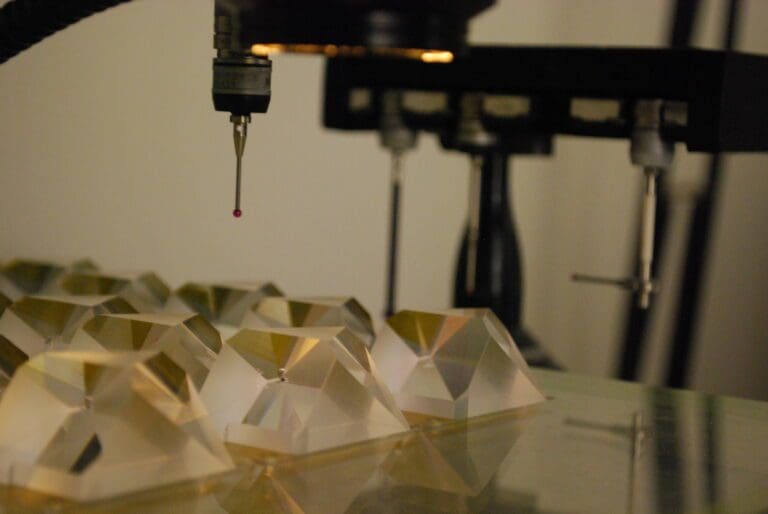

Our fully automated CMM (Coordinate Measuring Machine) systems are essential for mechanical inspections, providing touch probe and optical measurements to calculate prism dimensions.

These CMMs deliver accurate, non-invasive measurements for complex prism geometries, apex-to-datum distances, sharp edge specifications, and surface defect analysis (scratch/dig).

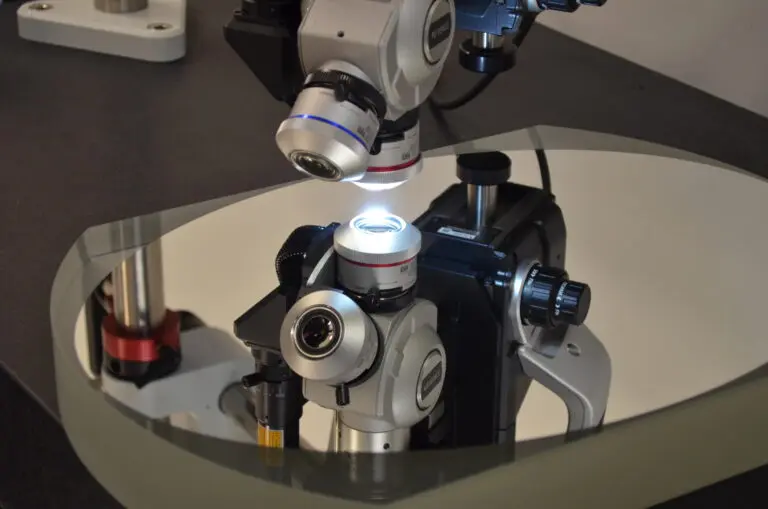

Our CMM capabilities are complemented by various standard metrology tools, such as digital micrometers, drop gauges, calipers, and optical microscopes.

The engineering team collaborates with the machine shop to create custom fixtures, enabling precise measurements of intricate optical components.