The optical quality standards for optical filters depend on multiple factors, including filter type (illumination or imaging/detection optics), microscope model, and intended use.

For instance, an emission filter used in laser scanning confocal microscopy demands different specifications than an excitation filter used in a standard widefield microscope for visual observation.

While detailing each filter type and application’s specific requirements isn’t feasible, understanding key optical quality parameters and basic microscope configurations can provide general guidelines for most cases.

Key Optical Quality Parameters

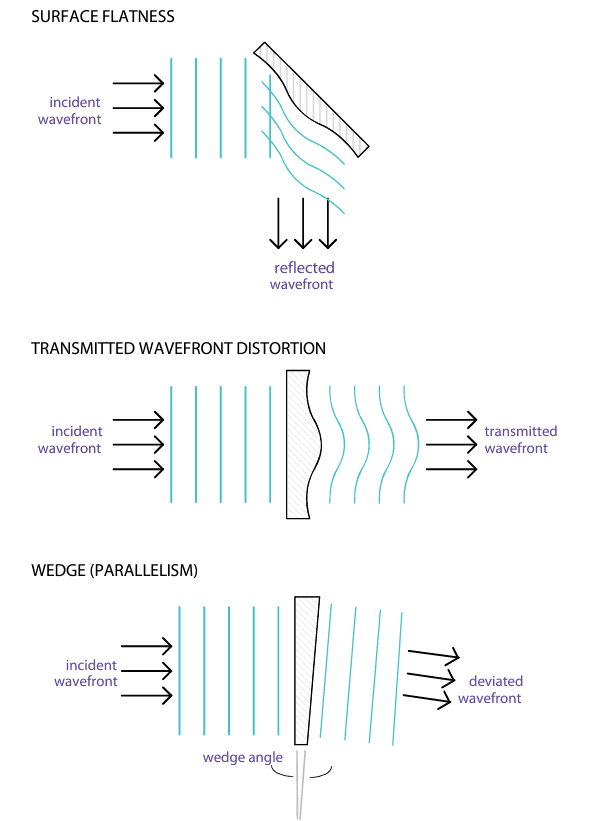

- Surface Flatness: Measures how close a filter’s surface is to a perfect plane, typically reported in fractions or multiples of visible light wavelengths (often 550 or 630 nm). Surface flatness affects reflected wavefront distortion (RWD), which can be twice the surface flatness value. Specifications for RWD generally reflect substrate flatness at normal incidence, but if true RWD is required, it should be explicitly specified.

- Transmitted Wavefront Distortion (TWD): Indicates how much a plane wave is distorted when transmitted through the filter, also measured in wavelength fractions. This parameter accounts for the outer surfaces’ flatness and, to a lesser degree, internal refractive index inhomogeneity.

- Wedge (Parallelism): Measures the angular alignment of a filter’s outer surfaces, typically in arc-minutes or arc-seconds. Wedge can cause light beams to deviate angularly, leading to image shifts. Internal coating surfaces with wedge alignment can cause ghost images from off-axis reflections.

- Clear Aperture: Ensures that the filter’s aperture matches the microscope’s aperture to prevent leakage of unfiltered light around the clear aperture. Filters are typically housed in rings to avoid leakage; if not, proper installation by the customer is required.

- Scratches and Digs: Reported using military-spec standards, such as “80/50 scratch/dig,” these indicate minor defects like particles, small bubbles, or inclusions.

- Pinholes: Small coating imperfections that create visible breaks, often due to dust particles during coating. Pinhole sizes must meet tolerance standards and can be evaluated under high-intensity lighting.

Optical Quality Requirements for Wide-Field Microscopes with Köhler Illumination

In wide-field epifluorescence systems with Köhler illumination, which creates a uniform field of illumination by positioning the arc lamp image out of focus at the specimen plane, key insights about filter requirements emerge:

- Excitation Filters and Dichroic Mirrors: As Köhler illumination focuses on specimen uniformity and flare minimization rather than precise light source imaging, excitation filters don’t require imaging-quality TWD. Similarly, the dichroic mirror’s surface flatness doesn’t need to meet imaging standards.

- Beamsplitter Alignment: Misalignment in beamsplitters can shift the illumination spot’s position on the specimen plane during filter cube switches. An alignment tolerance of 45 degrees ± 3 arc-minutes is typically sufficient, resulting in ±6 arc-minutes of angular deviation. Proper alignment during installation ensures minimal displacement.

- Wedge Effects: Wedge in the excitation filter shifts the illumination spot position without affecting the image’s registration. Wedge control should match dichroic mirror alignment tolerances within the filter block assembly.

- Filters in the Image Path: Filters in the imaging path, including dichroic beamsplitters and emission filters, require imaging-quality TWD to ensure optimal image clarity.

- Wedge Control in Emission Filters and Beamsplitters: Wedge in these components must be controlled tightly to avoid registration shifts during filter changes. Thickness variations in dichroic beamsplitters can cause registration shifts, especially in epifluorescence microscopes with standard tube-length optics that lack collimated imaging light.

- Pinholes in Excitation Filters: Positioned near the field diaphragm, pinholes in excitation filters are highly noticeable and should be minimized to avoid disrupting uniform illumination.

- Dichroic Beamsplitter Autofluorescence: As the beamsplitter receives full illumination from the excitation light and lies within the image path, minimizing its autofluorescence is critical.

Conclusion

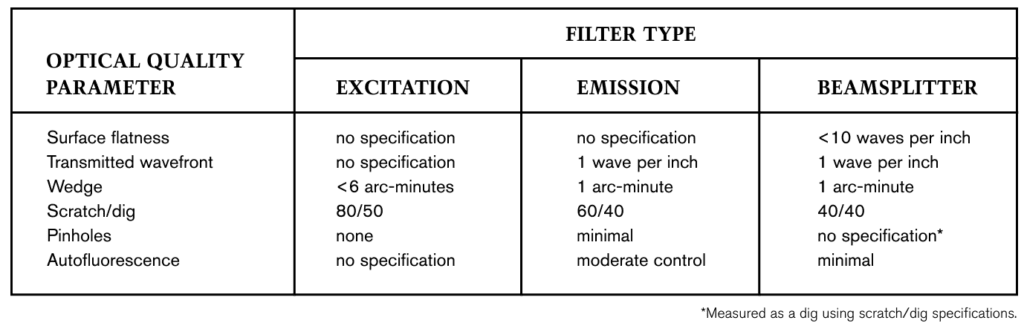

By understanding these parameters, optical quality requirements for wide-field epifluorescence microscopes can be summarized as seen in the Table below. This serves as a guideline for choosing appropriate filters based on the desired quality and application, optimizing image contrast and minimizing background noise.