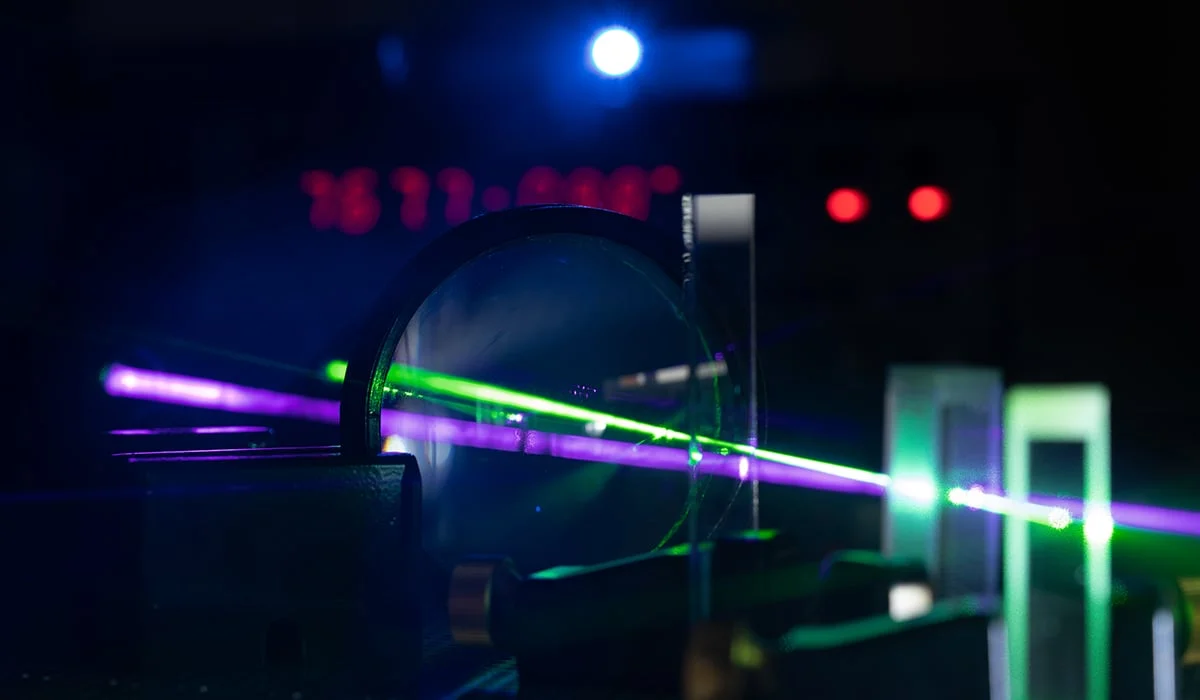

Photonics and electro-optics are pivotal technologies utilized across various devices and instruments that harness light for imaging, detection, excitation, illumination, and metrology, enabling analysis, measurement, and performance recording.

Our skilled engineering team comprehensively addresses specific system and market requirements, delivering cost-effective glass and coating solutions tailored for passive and optical protection, signal selection, environmental control, electro-optical interaction, and throughput efficiency.

CAPABILITIES

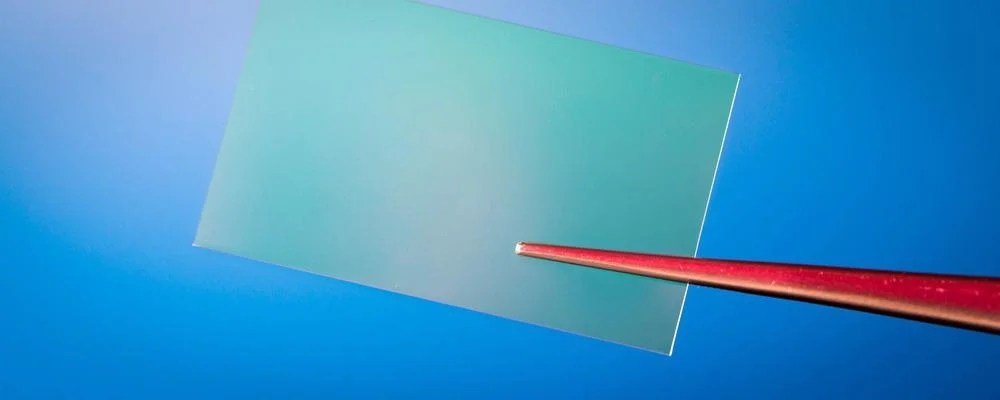

Substrates (Wafers & Sheets):

- Low/no alkaline – AF 32®, Eagle XG®, D 263®

- Thin (<,= 0.2mm) – D 263®

High durability – Corning® Gorilla®, SCHOTT Xensation, AGC Dragontrail™

- Soda lime (and low iron) w/broad angle AG

- Low expansion – Borofloat®, fused silica

Chemical Strengthening & Heat Tempering Glass Modification:

- Cutting, grinding, CNC machined features

Graphics (Semi-Transparent/Opaque):

- High-temp, epoxy, carbonless

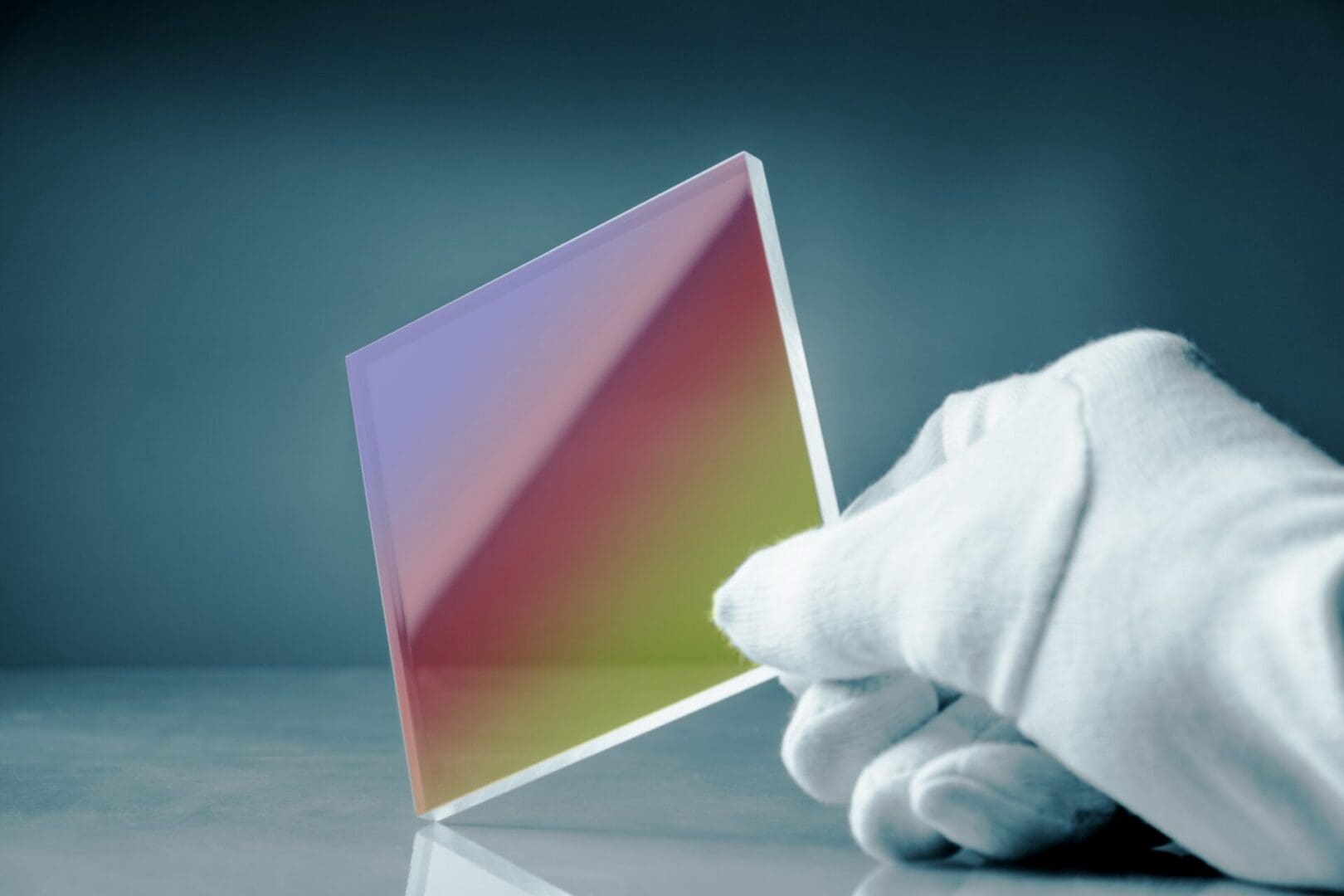

Coatings:

- Selective bandpass filter coatings

- Wavelength separation cut-on/off

- Excitation/emission filters

- Dichroic, color adjustment

- Hot/cold mirror/UV/solar blocking

- Mirror – metallic, dielectric

- Transmissive conductive (ITO)

- Oleophobic & anti-abrasive (steel wool)

Electrical Connectivity:

- Silver epoxy, silver frit, Cr/Ni/Au, In ultrasonic welded

Properties of Photonic Coatings

Photonic coatings are designed based on their optical characteristics and are widely applied in electronics, often involving biomimetic fabrication and surface-enhanced Raman scattering. These coatings improve the reflection, transmission, and polarization properties of optical components.

Without any coating, a standard glass component reflects approximately 4% of incident light at each surface. In contrast, applying an anti-reflective coating can reduce reflection to less than 0.1% per surface. Highly reflective dielectric coatings can push reflectivity to more than 99.99%. These coatings are generally made from metals, oxides, and rare earth materials, and their performance depends on both the number of layers and the refractive index of the materials used.

Photonic crystals, also known as photonic band-gap materials, are nanostructures engineered to control the movement of photons, much like semiconductors influence electron flow. Found in various natural forms, photonic crystals have been studied extensively for over a century.

These materials are crucial for managing light flow in optical systems and are used in creating high and low reflection coatings for lenses and mirrors. Additionally, they are employed in producing color-changing paints and inks.

Photonic Coatings for Optical Sensors

Research has shown that photonic coatings, which can respond to environmental changes, are extensively used in optical sensors, adaptive camouflage, and information encryption. Recently, scientists have developed humidity-sensitive, color-changing photonic polymer coatings based on hydrogen-bonded 3D blue phase liquid crystal networks.

The self-assembly of 3D photonic nanostructures, combined with strong covalent bonds between the polymers and substrate surfaces, is crucial in creating these vivid, structural color changes. These polymer coatings exhibit striking colors that shift with environmental changes.

Researchers have observed that reversible, humidity-induced color changes occur across the visible spectrum due to the breaking of hydrogen bonds, transforming the material into a hygroscopic polymer coating. This technology has the potential to be adapted for designing tunable 3D photonic nanostructures for applications in sensing, display technologies, anti-counterfeiting, and biomimetic camouflage.