What is an Enhanced or Protected Metal Coating?

Metal coatings are typically very delicate without a protective coating and require extra care during handling and cleaning. The surface of an unprotected metal coating should never be touched or cleaned with anything but clean, dry air.

A dielectric overcoat on a metallic mirror allows for improved handling of the component, increases the durability of the metal coating and provides protection from oxidation with little impact to the performance of the metal coating.

The dielectric layer(s) can also be designed to enhance the reflectance of the metal coating in specific spectral regions. Isopropyl alcohol or acetone can be used to clean our protected metal coated mirrors.

Protected Silver

Silver offers high reflectance in the visible and infrared spectral regions, making it an excellent choice for broadband applications that span multiple spectral regions. A protective coating reduces silver's tendency to tarnish but the coating still performs best in low humidity environments.

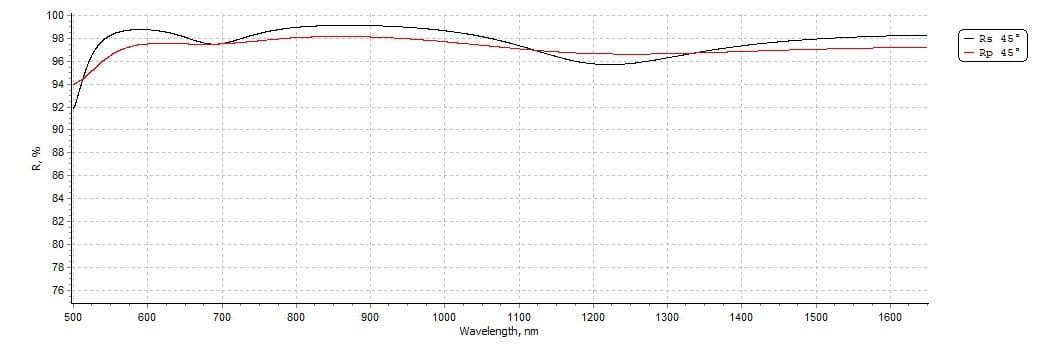

2nd Surface Enhanced Silver Mirror

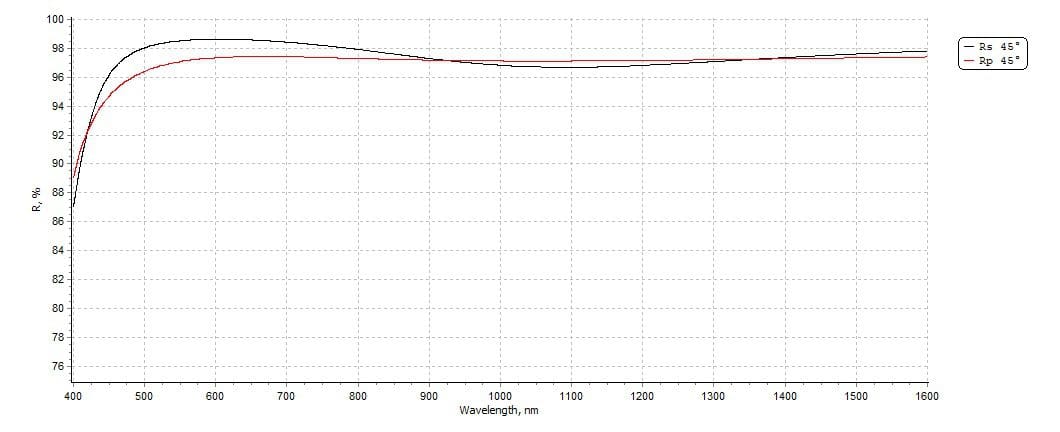

2nd Surface Protected Silver Mirror

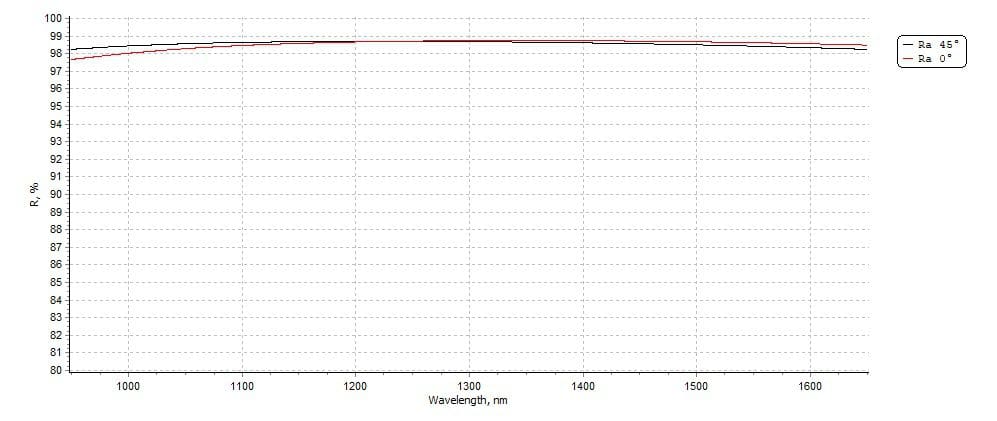

1st Surface Enhanced Silver Mirror at 632nm and 1550nm and 45° AOI

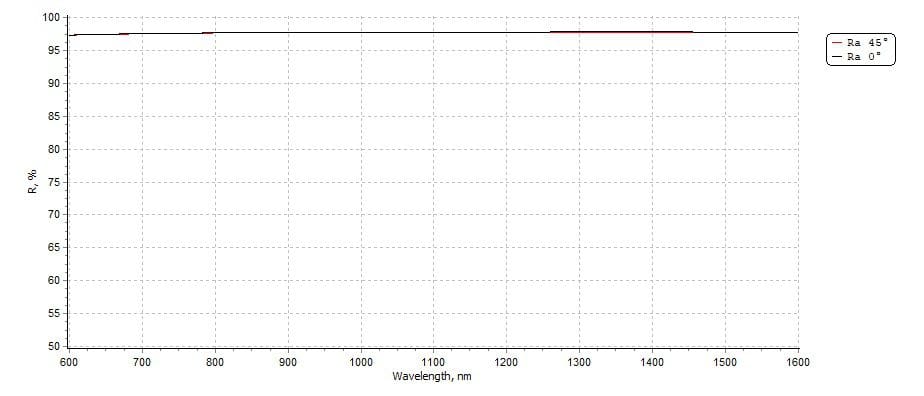

1st Surface Protected Silver Mirror at 632nm and 45° AOI