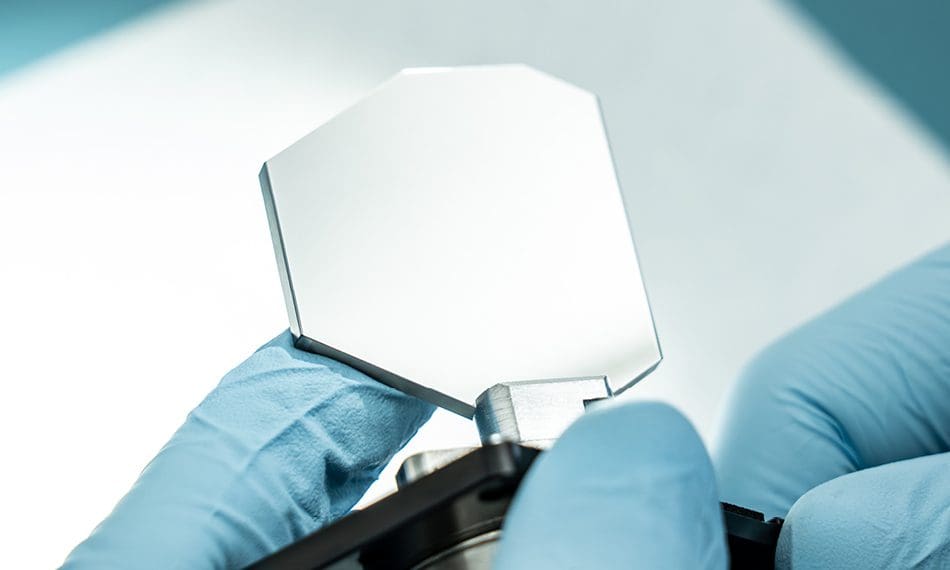

Optical Quality

Notch Optics maintains a rigorous Quality Assurance (QA) process to ensure that all products meet specified requirements. Our commitment to quality includes utilizing the latest testing and inspection methods to instill confidence in meeting stringent quality standards.

Key Quality Practices

Customer-Furnished Materials (CFM)

Environmental Compliance

Military Specifications

Standard Tolerances

Note: Specifications are subject to variations based on size, aspect ratio, and other factors requiring exceptions or deviations from standard tolerances.

Our customers appreciate our strong focus on quality, dedication to customer satisfaction, and rigorous process development aimed at prevention. Each division at Notch Optics continually evaluates key aspects of our processes and procedures to drive ongoing improvement initiatives. Our objective is to utilize Statistical Engineering tools for effective problem-solving, complemented by extensive in-house training and stringent procedures, making Notch Optics the preferred choice for precision glass optics solutions.

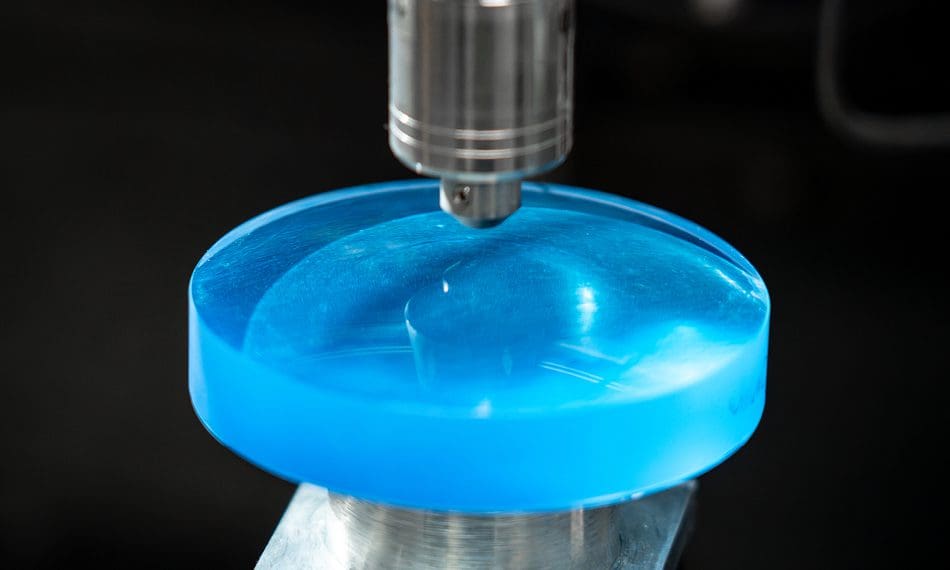

Notch Optics' Quality Management System is built on the foundation of the ISO 9001:2015 International Quality Standard. We strive for excellence through various Statistical Process Control (SPC) methods, including control charts, continuous improvement, and the design of experiments, alongside the implementation of 5S methodologies.

Our divisions are equipped to meet numerous industry quality standards and customer-specific requirements, encompassing ANSI, ASME, ASTM, NCSL, ISO, and MIL, such as MIL-PRF-13830B, DIS, JAN, and SAE.

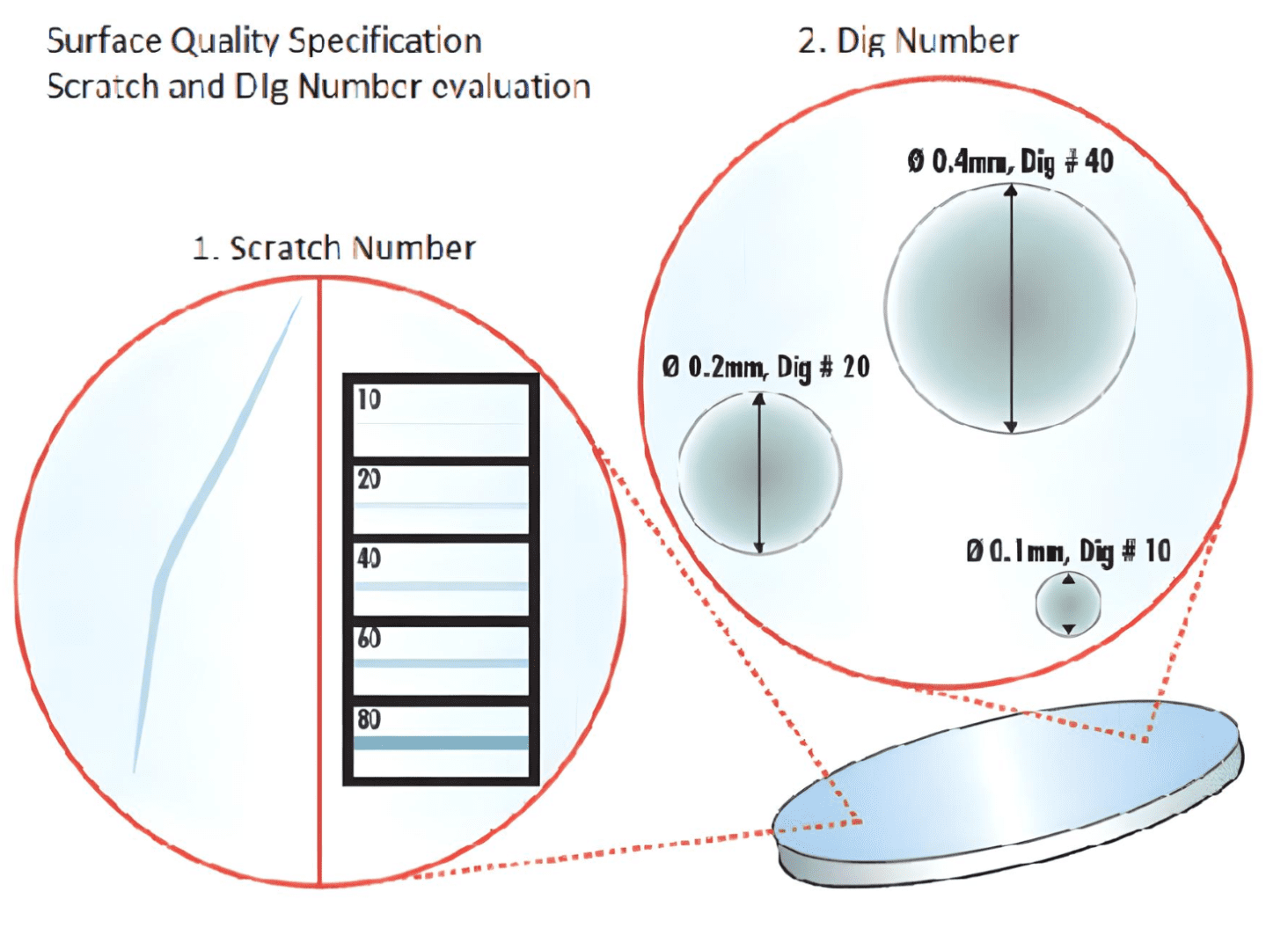

Specification Standards: Surface Quality can adhere to MIL-PRF-13830B and other applicable standards, tailored to specific application needs. This specification defines polish state, scratch resistance, and visual clarity.

Ensuring consistent results demands trained quality inspectors operating under standardized lighting conditions, overseen by Notch Optics' Quality Engineering team.

Definitions