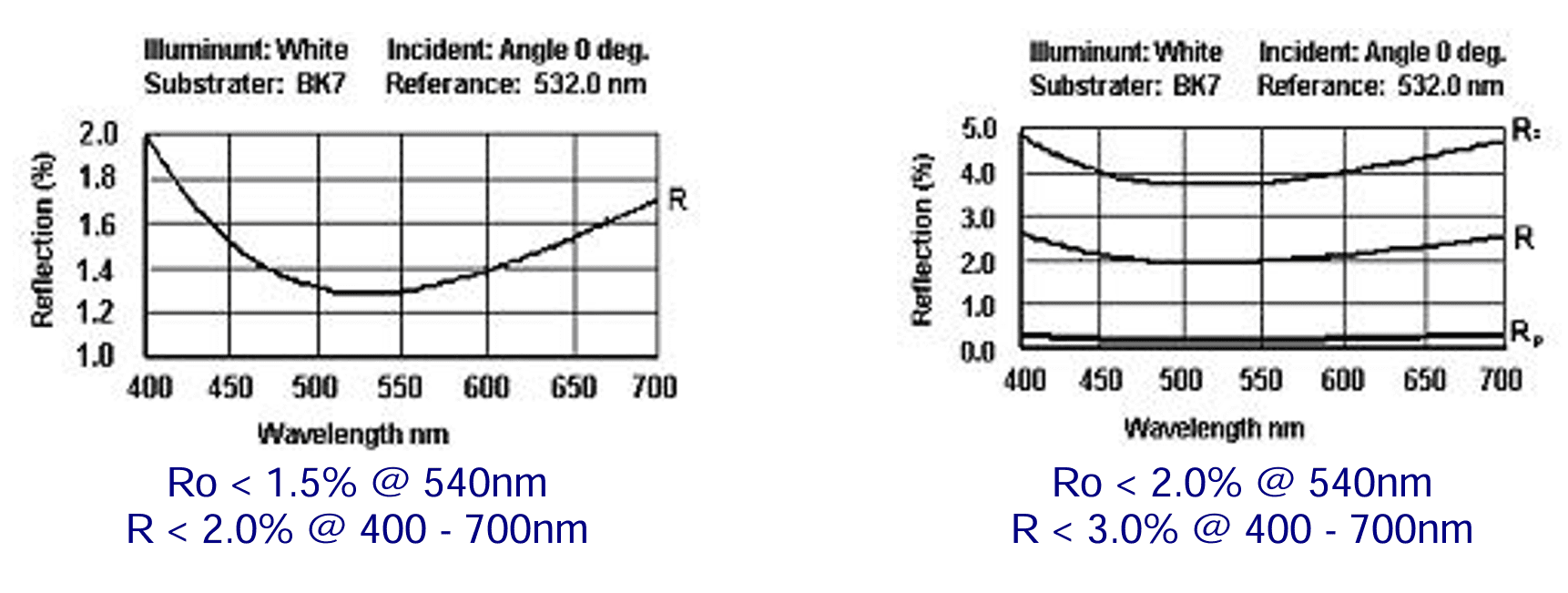

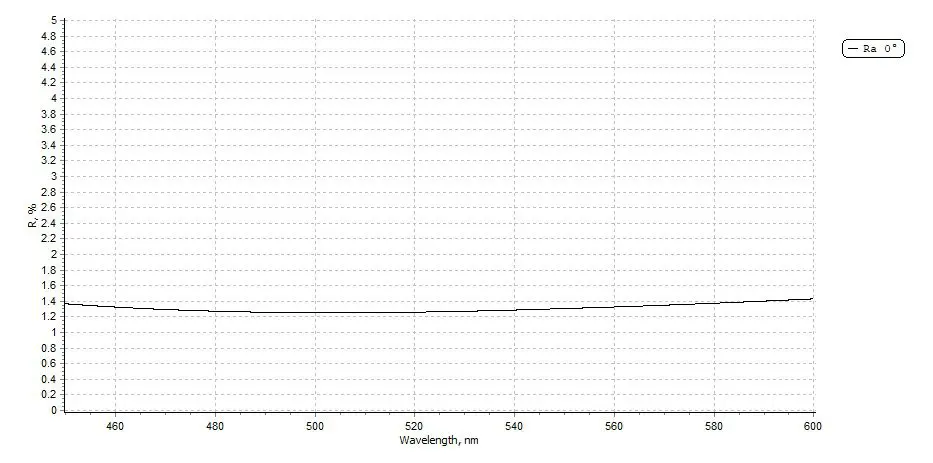

Many anti-reflective needs can be met with just a single layer of dielectric material applied to the substrate surface. The reflection is typically kept below 1.5%, depending on the refractive index of both the substrate and the coating material.

This approach is the oldest and simplest form of anti-reflective coating, offering durability and a lower cost compared to multi-layer coatings.

Single Layer MgF2 Antireflection Coating

Magnesium fluoride is the most widely used thin film material for optical coatings. Its performance is not outstanding but represents significant improvement compared with an uncoated surface. Because of the wide transmission range, MgF2 is an excellent coating material in UV wavelengths.

Single Layer MgF2 AR Coating Spectrum Curve

Detailed Explanation of Single Layer Anti-Reflection (AR) Coating

A single-layer anti-reflective (AR) coating is a thin film applied to a surface, typically made of a dielectric material, to reduce light reflection. It works by minimizing the reflection at the interface between the coating and the substrate. The coating is designed to create destructive interference for reflected light waves, thereby reducing the amount of light that bounces off the surface and increasing the amount of light that passes through.

Key Features of Single-Layer AR Coatings:

Material: The coating consists of a single layer of a dielectric material (non-conductive), such as magnesium fluoride (MgF2), deposited onto the substrate surface. The choice of material depends on the refractive index needed for the application.

How It Works: The refractive index of the coating is selected to be intermediate between the refractive index of the air and the substrate. This helps reduce the reflection by matching the impedance of the light wave as it passes through the different media.

Reflection Reduction: With a properly chosen refractive index, a single-layer AR coating can reduce reflection to less than 1.5% for a specific wavelength. The exact effectiveness depends on the refractive indices of the substrate and the coating material.

Advantages:

- Simplicity: It is the simplest type of AR coating to produce.

- Cost-Effective: It is less expensive than multi-layer coatings.

- Durability: The coatings tend to be durable and suitable for various applications.

Limitations:

- Limited Bandwidth: Single-layer coatings are most effective at a specific wavelength range. They may not perform as well across a broad spectrum of wavelengths compared to multi-layer AR coatings.

- Performance Constraints: For substrates with very high or low refractive indices, achieving optimal reflection reduction may be challenging with just a single layer.

Single-layer AR coatings are commonly used in simple optical applications where cost and durability are prioritized, and broadband performance is not essential.