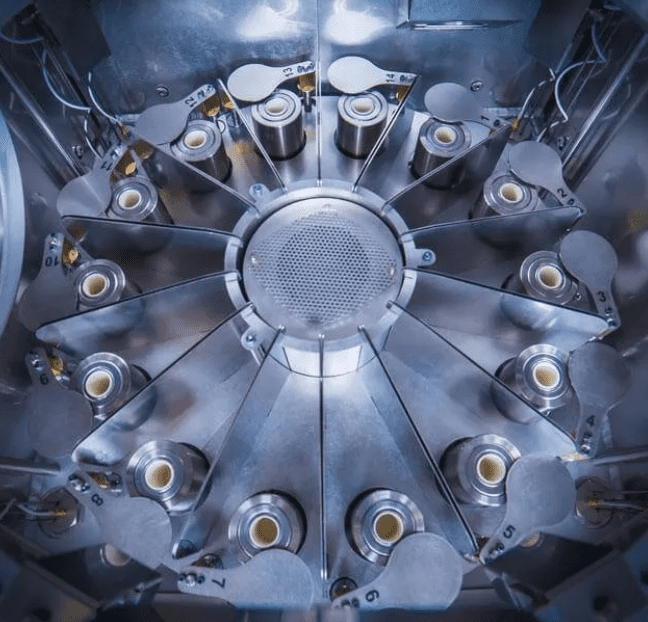

Notch Optics’ range of coating technology includes state-of-the-art methods, such as our Ion-Beam Sputtering chamber, as well as more traditional approaches like thermal evaporation.

Thermal Evaporation (or Physical Vapor Deposition “PVD”) uses a heat source to evaporate a solid material into a gaseous form within a vacuum environment.

This process deposits a thin film of the material onto the surface of a substrate, often glass. Commonly used for metallic coatings like aluminum, chrome, silver, and more, PVD is a cost-effective and efficient option for many reflective coating needs.

Notch Optics has over 23 years of experience with PVD coatings using a variety of materials for your applications.

How It Works

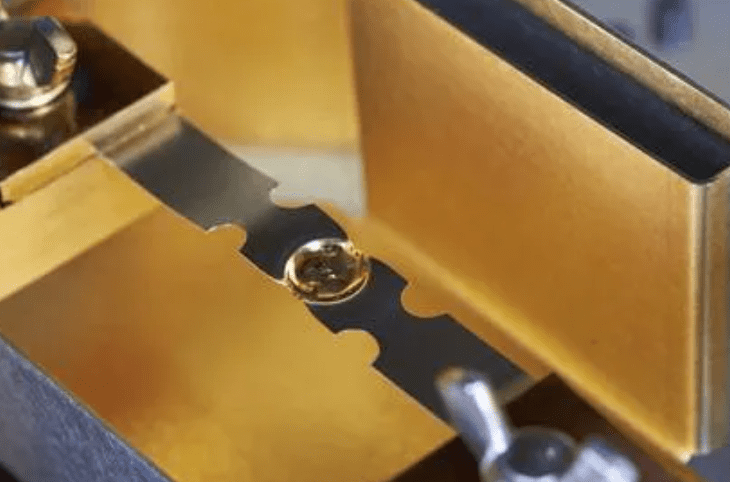

In this process, a material within a high-vacuum environment is heated to its evaporation point through joule heating of the resistive boat that contains it.

The vaporized molecules travel from the source to the substrate, where they nucleate, forming a thin film coating. This technique can be used to deposit a wide variety of materials, such as aluminum, silver, nickel, chrome, magnesium, and many others.

Importance of High Vacuum in Resistive Evaporation Processes

High vacuum is essential for resistive evaporation for two key reasons:

Unobstructed Travel for Vapor Molecules

In a high vacuum, gas is largely evacuated from the chamber, allowing vapor molecules to travel longer distances without colliding with gas molecules. Collisions are undesirable because they change the direction of the vapor molecules, which affects uniform coverage of the substrate.

When the gas pressure is below \(10^{-5}\) Torr, the mean free path (the average distance a vapor molecule travels before colliding) is typically over 1 meter, often longer than the chamber's dimensions.

This allows vapor molecules to travel directly from the source to the substrate, making resistive evaporation highly directional—a crucial quality for deposition in lift-off processes used in micro- and nano-fabrication systems.Ensuring Film Purity

High vacuum also plays a critical role in maintaining film purity. Background gases in the chamber, especially oxygen and moisture, can contaminate the growing film.

This is particularly significant in applications like organic light-emitting devices and organic photovoltaics, where the presence of oxygen or moisture can degrade the active functional components responsible for light emission or absorption.

By reducing these background gases to partial pressures below the \(10^{-6}\) Torr range, the purity of the evaporated films—and thus the quality of devices—improves significantly.