No coating department is complete without the proper testing equipment to ensure the quality and reliability of its products. At Notch Optics, we understand that thin-film coatings must not only perform optimally but also withstand the demanding operating conditions of the photonic systems or instruments in which they are used. These conditions often subject the coatings to extraordinary stress, making durability a critical factor in their design and performance.

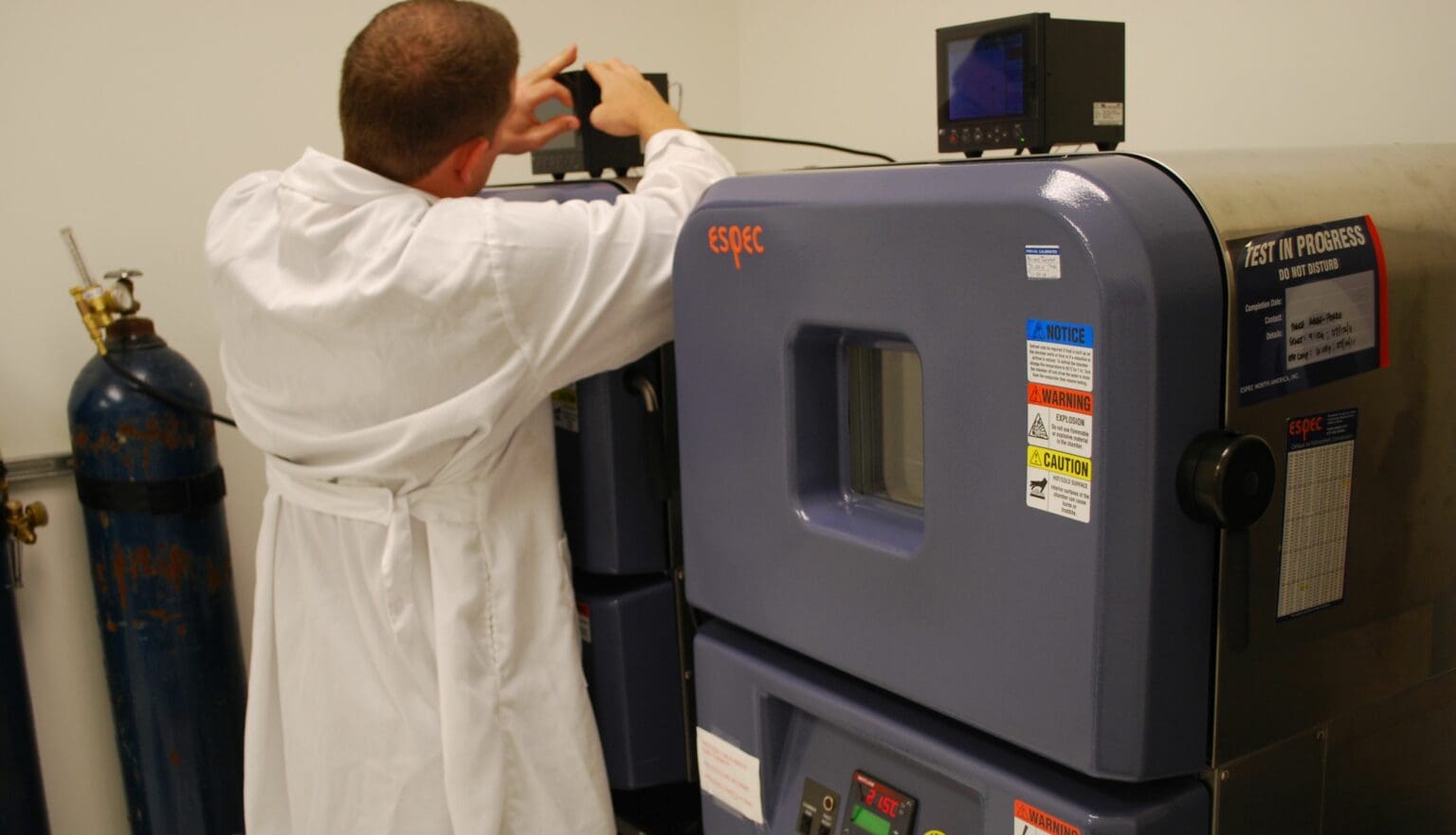

To ensure that our coatings meet these rigorous demands, we rely on a suite of advanced testing equipment specifically designed to evaluate their resilience and functionality. Thin-film coatings are subjected to thermal, humidity, and environmental testing to simulate the real-world conditions they will encounter. These tests replicate extreme temperature fluctuations, high-humidity environments, and exposure to harsh environmental factors, providing valuable insights into the coatings' performance over time.

For thermal testing, specialized equipment evaluates how coatings react to both intense heat and freezing conditions, ensuring that they maintain their optical properties and structural integrity. Humidity testing subjects the coatings to prolonged exposure to moisture, checking for potential degradation or delamination. Additionally, environmental testing chambers simulate conditions such as rapid temperature changes, salt spray, and dust exposure, which are common in many industrial and aerospace applications.

This comprehensive approach allows Notch Optics to refine and perfect its coating processes, ensuring that every product meets or exceeds industry standards for durability and reliability. By combining cutting-edge technology with rigorous testing protocols, Notch Optics guarantees that its coatings are fully prepared to thrive in the most challenging environments, providing customers with the confidence they need for their critical applications.